Singlespeed Chain & Belt Tensioning System:

Eccentric Bottom Bracket

Two popular methods exist for tensioning a chain without an external derailleur:

- Adjustable dropouts: Slider dropouts, for example, where the dropout moves to set chain or belt tension.

- Eccentric bottom bracket (EBB) where the bottom bracket system rotates eccentrically to adjust chain or belt tension.

Both systems have pros and cons. Seven offers only the EBB system for single cog chain and belt tensioning. We do not offer adjustable dropouts of any kind, including slider-style and rocker-type dropouts.

Seven has built over a thousand custom singlespeed, belt drive, and eccentric bottom bracket specialty bikes over the past 29 years. (Our founding engineer built his first chain tension bike more than 39 years ago.) That's probably more years and more custom frames with EBBs and adjustable dropouts than any other builder. We even had our own proprietary slider dropout system for years. And it that's not enough, we built the bike on which Mo Bruno Roy won her Singlespeed World Championship title.

We've learned the pros and cons better than most. So, when we chose to stop offering adjustable dropouts, it was for good reasons.

Why choose an EBB instead of slider or adjustable dropouts?

| EBB Benefits | Reason for Benefits |

|---|---|

| Easier to adjust and fine-tune chain tension |

Sliders require adjustment at both dropouts with a total of 4 to 6 adjustment bolts. EBBs have a single adjustment bolt. Fine-tuning chain tension is done with a 4 mm hex wrench in one simple and easy adjustment. |

| No need for tedious wheel and rotor alignment | Tensioning sliders requires adjustment at both dropouts while getting the wheel and brake rotor aligned perfectly. EBB's single tensioning point is isolated from wheel and rotor; no adjustment needed. |

| Compatible with nearly every single Seven model, feature, and option | Drivetrain options: Our EBB works seamlessly with all of Seven's chainstay configurations.

☑ Bottom bracket widths: We offer EBB in 68, 73, and 100 mm widths. Therefore, we can build virtually any type of bike for singlespeed use including road, gravel, mountain, boost, super boost, and fat. (Many adjustable dropout systems also allow for these options.) ☑ Disc brake options: Available for post mount, flat mount, and even caliper rim brake options. ☑ Universal Derailleur Hanger (UDH) available: This option is available with Seven's chain tensioning system. ☑ Derailleur optional: We can provide a derailleur hanger or not. Seven's UDH system makes this particularly simple. (Many adjustable dropout systems also allow for these options.) |

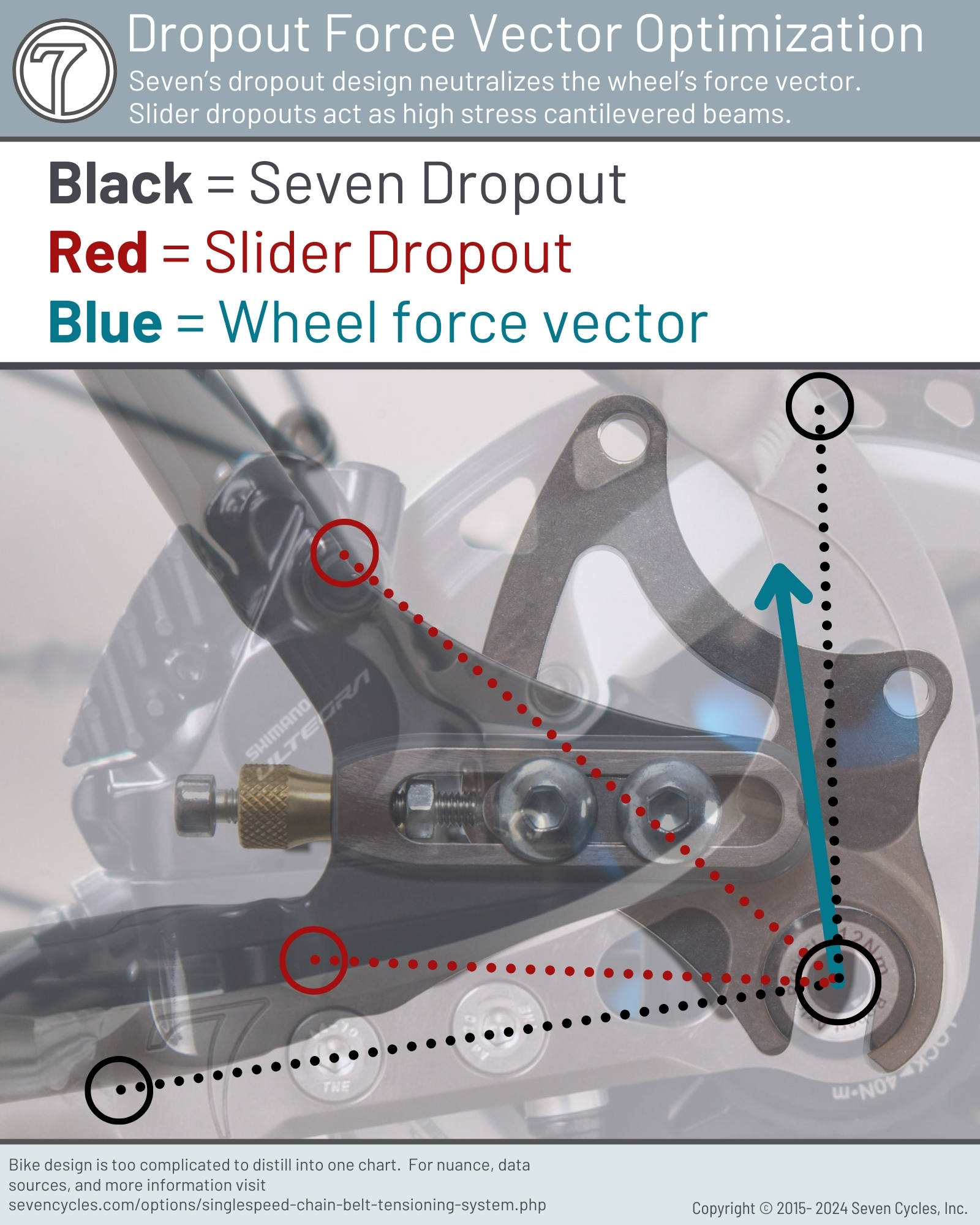

| Long term durability | 1). Cantilevered dropout designs have durability challenges. See Figure 1, Figure 2, and the durability information for details.

2). Seven's oversized chainstay stiffness creates a discontinuity with the diminutive and relatively flexible adjustable style dropouts, pushing beyond their durability limits. See Seven's dropout durability table. |

| Improved acceleration and power transfer | First, Seven's dropout is three to five times stiffer than popular adjustable dropouts. See the Dropout Stiffness & Durability table for the math. |

| Second, Seven's standard chainstay design is about 30% stiffer than other popular titanium drivetrains. (Seven also offers chainstay profiles that are more than 200% the stiffness of other popular titanium chainstays.) Seven's chainstay stiffness must be matched with stiffer dropouts. | |

| Third, the EBB system itself is significantly stiffer than standard bottom bracket systems, featuring a larger diameter and a stout insert design. Like a T47 bottom bracket but even larger and stiffer. | |

| Works with flat-mount and post-mount disc brakes | UDH slider systems are not (yet) compatible with flat-mount brakes. Most gravel bikes and the lightest disc brakes are flat-mount. |

| EBB Considerations | Reason for Consideration |

|---|---|

| Not compatible with internal housing and internal wiring | The eccentric bottom bracket housing does not work with Seven's internal housing routing method. Seven only offers internal routing that runs through the bottom bracket shell; this provides maximum durability of the internal routing. The eccentric interferes with internal access ports. |

| 116 grams heavier than the lightest slider dropout system. | Added weight due to the oversized bottom bracket shell plus the expanding cartridge. |

| EBB Myths | Reality |

|---|---|

| Reputation for creaking | Proper maintenance eliminates creaking. Improper assembly causes creaking. EBB has far fewer creakable parts (6 vs. ~14) that can cause noise when not properly maintained. |

| Can be confusing to adjust | Adjusting the system requires only one 4 mm hex wrench but can be confusing if the mechanic doesn't read the assembly instructions. |

| Complex internals | Typical slider dropouts have 14 assembly parts. Seven's EBB has 6 assembly parts that are all contained as one for the user. EBB has 1 bolt adjustment vs. 4+ bolts for sliders. |

Weight Comparison of Slider Dropouts Vs. EBB

We used slider dropouts for our weight comparison because they are the lightest of the adjustable dropout family.

Weight comparison can be confusing because we're not just adding parts (and weight) but also replacing some parts, and therefore modifying weight rather than just adding or subtracting.

| Compared to Seven's Geared Bike Dropout System[3] | Compared to Seven's Geared Bike UDH System[3] | |

|---|---|---|

| Seven's Eccentric Bottom Bracket (EBB) System[1] | +177 g (6.2 oz) |

+177 g (6.2 oz) |

| Slider dropouts[1] [2] | +61 g (2.2 oz) |

+65 g (2.3 oz) |

| Seven's EBB system is heavier than the lightest slider system by about[3] | +116 g (4.1 oz) |

+112 g (4.0 oz) |

Dropout Stiffness & Durability

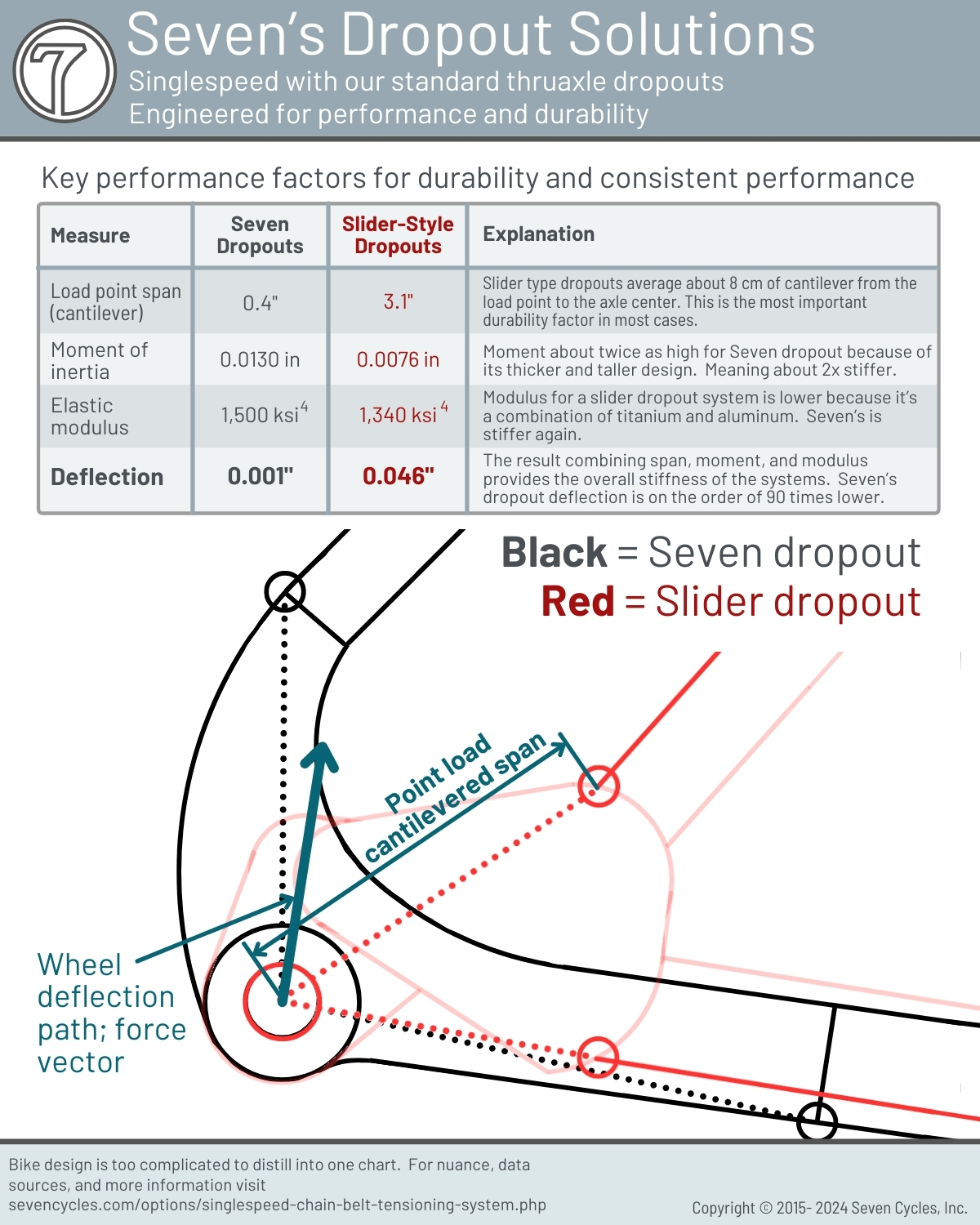

Figure 1 provides a visual representation of the difference between load points of the Seven dropout system and a typical slider-type dropout.

This table explains the significant discrepancy between the two dropout engineering approaches.

| Measure | Seven Dropouts | Slider-Style Dropouts | Description & Explanation |

|---|---|---|---|

| Cantilevered load point span | 0.4" | 3.1" | To suggest that Seven has any load point distance or span at all is generous. Our dropout places our load point in the most protected spot — directly above the wheel's axle. (See Figure 1 and Figure 2.) Slider-type dropouts average about 8 cm of unsupported distance from the maximum load point to the axle center. This is the most important durability factor in most use cases. It is the largest factor in overall part deflection. |

| Moment of inertia | 0.0130 in4 | 0.0076 in4 | Seven's dropouts are 40%+ thicker and 60%+ taller. This makes the moment nearly 2x of popular slider dropouts. The result is a significantly stiffer and stronger Seven dropout. |

| Elastic modulus | 1,500 ksi | 1,340 ksi | Both dropout systems are titanium, so you might expect that the modulus would be identical. However, slider-style dropouts also employ aluminum inserts for wheel axle connection. Aluminum accounts for about 1/3 to 1/2 of the span's stiffness from axle to frame tube contact point. Aluminum's modulus is about 30% lower than titanium's. In this case, we conservatively calculate aluminum to account for 1/3 of the overall structural stiffness loss of the slider dropout system. |

| Deflection | 0.00005" | 0.046" | As shown above, the load point span, moment of inertia, and modulus each factor heavily into the stiffness performance of dropout designs. Seven's dropouts are on the order of 900 times stiffer than a typical slider. (deflection of 0.049" divided by 0.00005" is 920 times greater.)

Of course, there is more to building a frame than these simple engineering concerns, but any elements we add to this equation increase the disparity between Seven's dropouts and any possible alternative. |

Footnotes and math proofs

For the people out there that want to understand Seven's math and data claims:

System Weight Data

These data are for individual part weights as required to weld into a real-world frame.

Slider dropout system w/ replaceable hanger

297 g total weight

107 g conventional sliders, pair

75 g post-type brake mount aluminum insert

55 g flat mount insert (no hardware)

~33 g hardware, nuts, bolts, washers

27 g = + 10 cm extra chainstay tubing length

Slider dropout system w/ universal derailleur hanger

301 g total weight

107 g conventional sliders, pair

89 g UDH post-type brake mount aluminum insert

45 g UDH driveside insert no hardware (no hardware)

~33 g hardware, nuts, bolts, washers

27 g = + 10 cm extra chainstay tubing length

Seven eccentric bottom bracket system (standard hanger or UDH system)

261 g total weight

128 g eccentric titanium shell, width 68 mm

140 g eccentric expanding insert, including hardware

-7 g tubing length reduction

Reference weights: Seven standard SL dropout system & bottom bracket

194 g dropouts, pair, including axle hardware

42 g disc brake mount insert + hardware

84 g Seven T47 threaded shell 68 mm width