Testing

We are committed to delivering the highest quality products possible, and that means we are obsessed with the details of your frame, including many aspects that the untrained eye would never notice.

Here are a few examples:

- Our proprietary tube butting technologies hold wall thickness variations to within 0.001" - the thickness of a human hair. Tolerances this tight are critical to controlling elements such as weight, stiffness, compliance, and durability.

- Every Seven is subjected to no less than 50 alignment checks—28 in welding alone. Each is designed to guarantee the straightest, most accurate frame possible. This is crucial to ensuring proper bike handling.

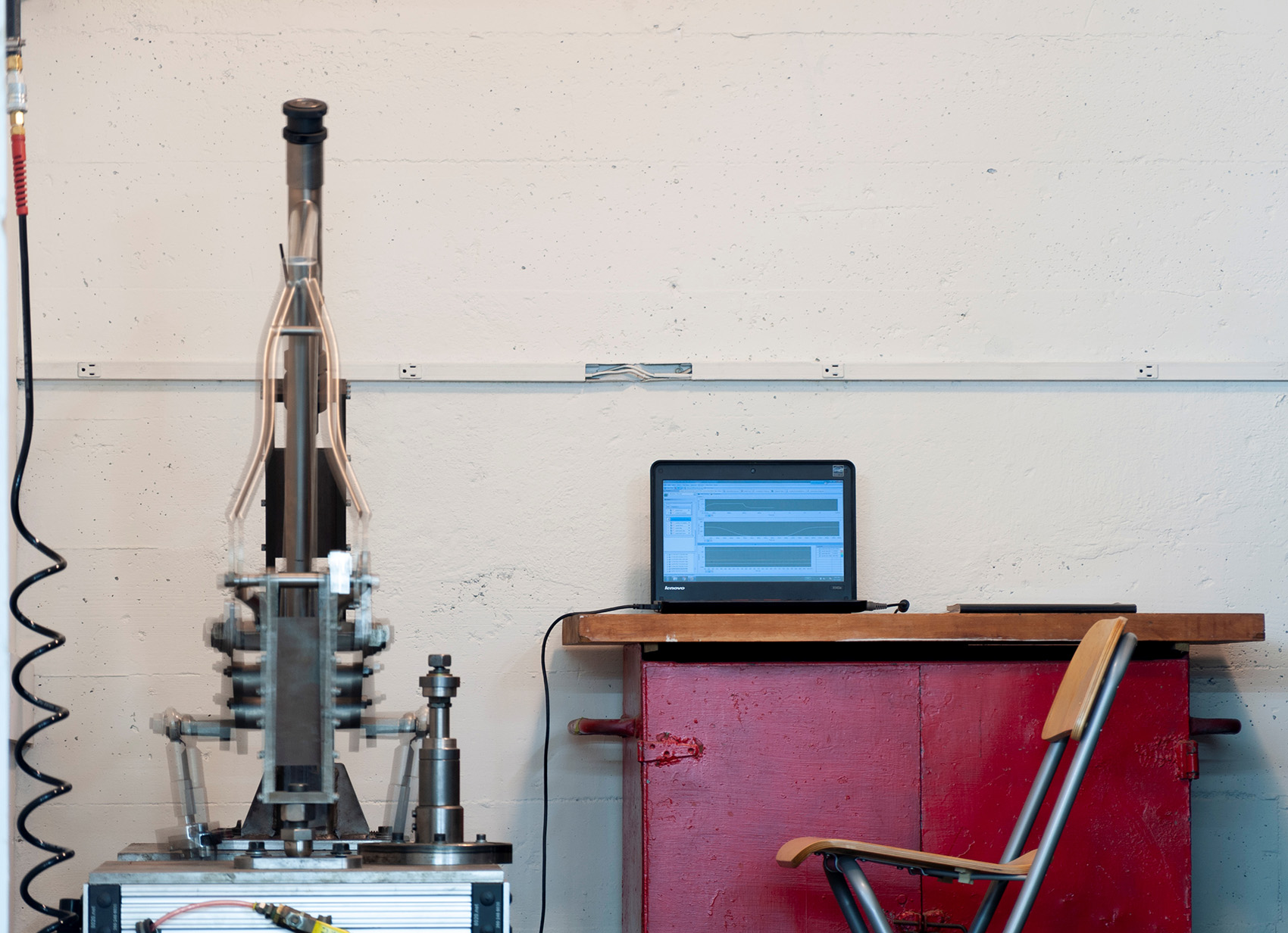

- We designed our own in-house fatigue testing machine specifically to test riding-specific stresses. Performing our own tests allow us to assure the safety and reliability of everything we make.

This is just a glimpse of the painstaking efforts we take to ensure no detail is overlooked. Is that obsessive? Perhaps. But taking any other approach with your bike is not an option.