Seven's Integrated Derailleur Hanger

The best of all worlds

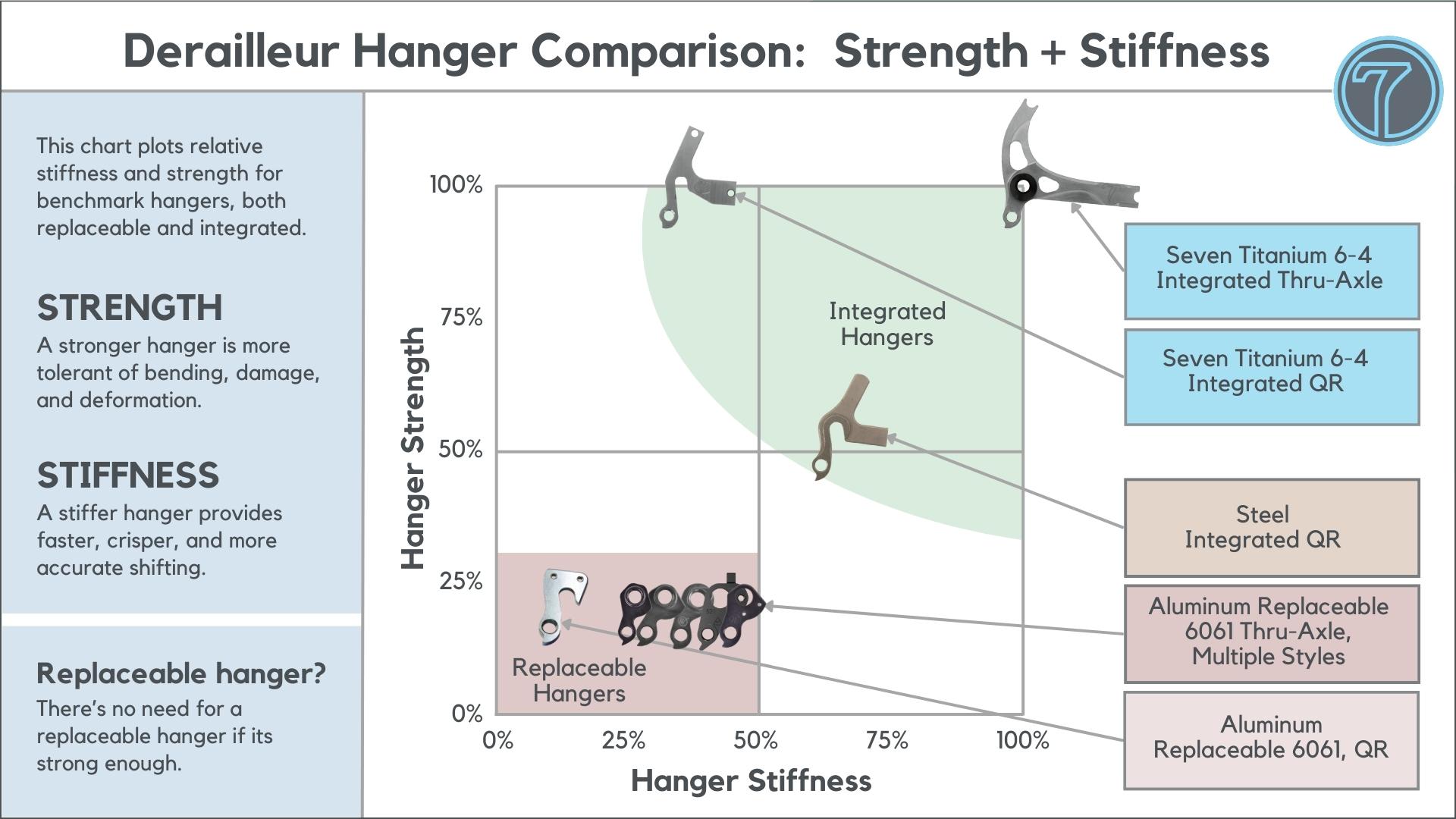

Did you know that Seven has the stiffest and strongest derailleur hanger made? The strength-stiffness chart below shows where the most popular and historically important derailleur hangers lay on the stiffness-strength scale. Seven's thru-axle integrated hanger dropout sets the standard on both axes of the scale. No replaceable hanger — UDH or otherwise — even comes close. This is not to say that the SRAM UDH Transmission derailleur isn't interesting, but the UDH itself, when used with a standard derailleur, significantly under-performs Seven's hanger design.

How is all of this possible? Three primary reasons:

- 4x stronger: The 6-4 titanium alloy we use for our dropouts is about 430% stronger than the 6061 T6 aluminum alloy that many hangers use. (~160,000 psi vs. ~37,000 psi.)

- 2x thicker cross-section: Seven's thru-axle hanger has about a 190% larger cross-section at its load leverage point than the average aluminum, replaceable hanger.

- Integrated hanger removes all the weakest points on a replaceable hanger: Stress risers and the thinnest sections at highest load points.

Bent derailleur hanger? While extremely unlikely, it is possible to bend Seven's integrated hanger. However, it is easy to straighten it with any standard derailleur hanger tool.

Destroyed derailleur hanger? Seven has never had a thru-axle hanger get destroyed. That's many thousands of bikes. We have had a few QR hangers get damaged beyond straightening. Fortunately, we've saved 100% of the few frames that have had major damage. And that hanger is still stronger than any other hanger in the world.