If Monocoque Carbon Frames Were Built Like Carbon Forks and Wheels, Frames Would Ride Better

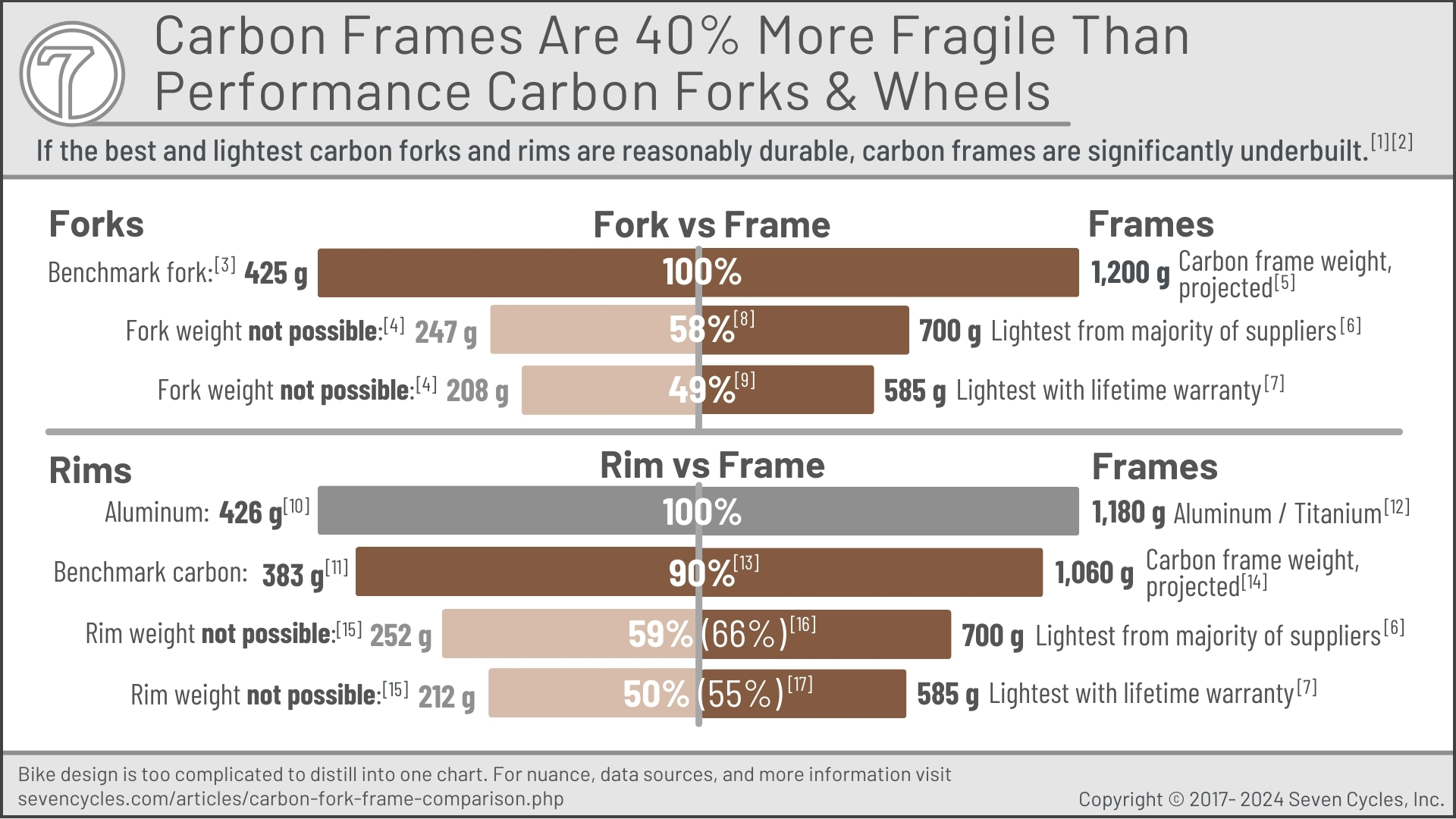

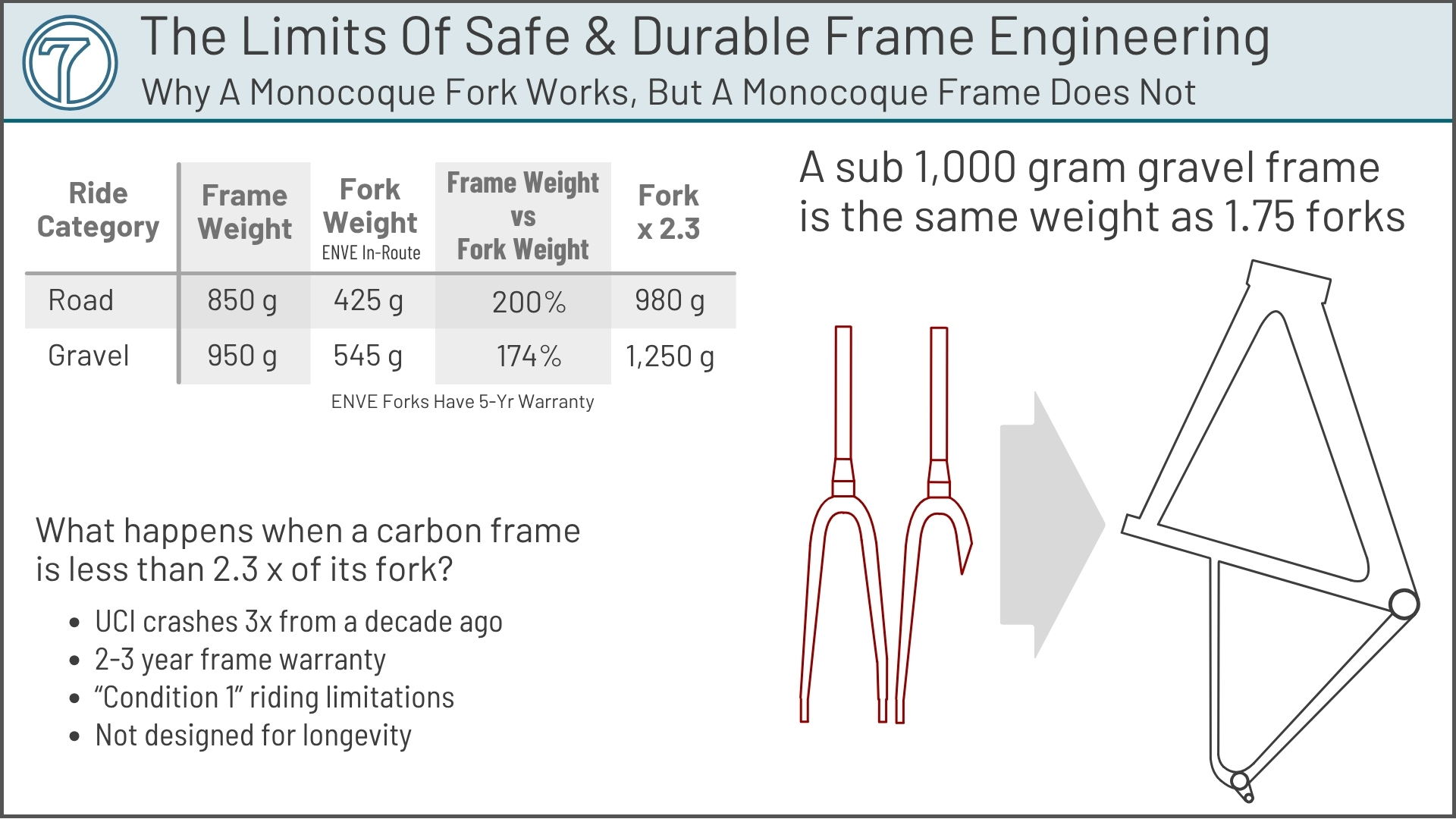

The lightest carbon road forks weigh about 425 grams. The lightest carbon road frames weigh about 700 grams. These forks weigh 60% of frames, but have only 30% of the surface area, and are much simpler product. In short, if forks are properly built, frames are severely underbuilt and much too light. Frame performance, durability, and safety are all crippled by this difference.

It is no coincidence that the lightest carbon forks and carbon rims both have 40% to 50% more material per square centimeter of external surface area than the lightest carbon frames. This may be the most useful datapoint to show how underbuilt many carbon frames are.

Rims and forks are relatively simple structures compared to frames. This means that forks and rims should be proportionally lighter, relative to surface area, not heavier than frames. However, the opposite is true; light carbon frames are about half the material per centimeter of the lightest carbon forks and rims.

We compare carbon frames to carbon forks in this first section. We compare carbon frames to carbon wheels in the second section.

Comparing Frames & Forks

"If monocoque carbon is so terrible, why does Seven use monocoque carbon forks for their framesets?"

That's a good question, and it gets to the heart of the problem with modern monocoque frames. In short, if bike brands sourced frames built like forks, poor frame fatigue, weak impact resistance, and general durability issues would be less problematic. Figure 1 above illustrates the discrepancy between frame and fork engineering.

The table below describes the deficiencies in frames compared to forks. By nearly every measure, forks are built better, more robust, tougher, and yet have shorter warranty commitments.

In the table below, we use Enve as the fork standard because no one could argue that Enve is not reputable. We don't use Seven's forks for this comparison because some readers might think we are biased.

| Carbon Aspect Compared | Carbon Monocoque Road Disc Frame | Carbon Road Disc Fork |

|---|---|---|

| Frame Weight | 585 to 900 grams

Most high-end carbon frame suppliers make a road bike in the 750-gram range. |

425 grams

Enve road In-Route. This is over 50% of lightweight carbon road frames. Given that a fork has about one-third of a frame's external surface area, the lightest carbon frames are underbuilt by more than 54%. |

| Condition 1 Limitations | Probably the single most condemning aspect of carbon frame problems is Condition 1 limitations. Example text from Condition 1 warranty limitations: "you are choosing light weight [...] over a longer frame life" |

Condition 1 forks weigh 425 grams or more. |

| Complexity of Structure & Stress | Frames undergo complex stress (relative to forks) and therefore should be disproportionately heavier than forks (for a given surface area). Even FEA computer models cannot adequately mimic the stresses a frame undergoes. Part of this is because bicycles are chain-driven, which induces significant torsion in the frame that is not easily mapped or accounted for. | Forks have relatively simple stress modes. It's fore-aft primarily, with some lateral (side-to-side). The only torsional stress comes from the disc brake, but the frame also has one, so that difference is negated in any weight comparison. |

| Warranty | Lifetime warranties from the largest carbon bike suppliers. These brands include Trek, Specialized, Cannondale, and Giant. | 5 years. No reputable carbon fork manufacturer offers a lifetime warranty. If frames were not underbuilt, it would be very odd for forks not to have a lifetime warranty, given that forks are much heavier (per unit of external surface area) and have much simpler structural requirements (limited torsional stress, as explained above). |

| Weight Limit | Bike brand weight limits vary, but are generally in line with fork weight limits. The four largest brands have an average weight limit of 294 lbs: Specialized, Trek, Cannondale, and Giant. More details below. |

Reputable carbon forks have a similar weight range to that of performance carbon frames (240 to 300 lbs.). Enve's weight limit for their disc forks is 300 lbs. Whisky brand forks have a rider weight limit of 240 to 300 lbs., depending on model and use case. Columbus fork rider limits are 242 to 253 lbs. |

Fatigue Testing Standards Lay Bare The Carbon Frame Problem

The bike industry uses ISO 4210-6 testing standards for frames and forks. This standard has at least three test parameters that show frames are treated with kid gloves compared to forks. The three are shown in the table below.

We mention ISO 4210-6 because that's what the industry uses; however, Seven tests well beyond the 4210 standard. Most bike test companies agree that 4210 sets the lower threshold, not the target. Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily. Having frames and forks meet the standard is not that impressive. Seven tests past the 4210 standard.

Here's what Zedler-Group Zedler-Group. testing has to say about the adequacy of 4210-6 standards:

"The ISO 4210 standard for bike tests sets a floor, not a ceiling." Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily.

"Testing to ISO 4210 alone does not make for a safe bike." Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily.

Testing "bikes in accordance with ISO 4210, it is not enough — and does not by itself ensure a safe bicycle." Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily.

"For this reason, some [...] manufacturers have developed their own testing requirements that go beyond ISO 4210." Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily.

| ISO 4210-6 Test Standard ISO 4210 standards. Must be purchased to read the complete standards. | Carbon Frame | Carbon Fork | Difference Between Frame And Fork Testing |

|---|---|---|---|

| Fatigue Load & Cycles | 1,100 Newtons at 100,000 fully reversed cycles | 620 Newtons at 100,000 fully reversed cycles | Fork test weight is about 56% of the frame test weight.

This indicates that forks undergo significantly less stress than frames. The reason is that forks don't see much torsional stress; frames do, because they're chain-driven. |

| Indication of Failure | The ISO standard is silent on this. ISO 4210 standards. Must be purchased to read the complete standards. The DIN 14781 standards DO specify a 20% stiffness loss as failing the test. The ISO 4210 standards have superseded the DIN 14781 standards have been superseded by the ISO 4210 standards. The DIN standards must be purchased to read the complete details. No explanation for why this was removed from the newer standard has been given. The ISO 4210 standards have superseded the DIN test standards. |

A 20% stiffness reduction or "fractures found" ISO 4210 standards. Must be purchased to read the complete standards. | Frames are allowed to get infinitely flexible under the 4210-6.4.3 test standard. Forks, conversely, are considered failed at 20% stiffness loss under the 4210-6.5.5 test standard. This flex-to-infinity standard makes no sense when it comes to safety. |

| Impact Test | 212 mm drop distance (this test is done with the fork installed.) | 640 mm drop distance (this is for the fork alone.) | The frame's drop weight height is 33% of the fork alone. This doesn't make any sense. If one expects the fork to get hit with X impact, why would the frame and fork combined get hit (in the same way), at only one-third of the fork's impact. The discrepancy is a known issue with the 4210 testing protocol. Zedler, D., 2017, The ISO 4210 standard for bike tests sets a floor, not a ceiling, Eurobike Show Daily.

This 66% difference in expectation shows that frame fatigue standards are more forgiving than those of forks. |

Comparing Frames & Wheels

"If monocoque carbon frames are so terrible, why are carbon wheels so popular?"

The weight difference between the lightest carbon rims and the lightest aluminum rims is about 10%, as shown in the table below. The lightest carbon frames are about 40% lighter than the lightest durable titanium (or aluminum) frames. If carbon rims were 40% lighter than aluminum rims, they would weigh 250 grams; that would make for hazardous riding.

Similar to the carbon fork comparison above, riders sometimes ask us about frame comparisons with carbon wheels. The logic is that if carbon wheels work well, carbon frames must be fine, too. However, if the lightest carbon rims weighed proportionately the same as the lightest carbon frames, the rims would weigh about 250 grams, or about 40% less. There is no way to build a carbon rim anywhere near that weight, yet many carbon frames are built in that 40% overly light range.

Fortunately, it's straightforward to demonstrate how underbuilt carbon frames compare to carbon rims. This is because we can compare metal (aluminum) rims to carbon equivalents and thereby make some inferences about metal (aluminum and titanium) frames compared to carbon frames.

If the lightest carbon frames were only 10% lighter than the lightest durable titanium or aluminum frames, we might have some durable carbon frames. However, the lightest titanium frames that still have some modicum of durability weigh in at about 1,180 grams or more. The lightest carbon frames are about 600 to 700 grams. That's a 40% variance, as illustrated in Figure 1. If carbon rims were 40% lighter than aluminum rims, the carbon would not hold up.

Rim Weight Comparison: Carbon Vs Aluminum

This table lists three comparisons of carbon and aluminum performance road rims. These show that lightweight carbon rims are consistently about 10% lighter than the lightest aluminum rims.

Not many rim makers offer both aluminum and carbon rims anymore. Comparisons across brands are sometimes necessary. Regardless, the results are consistent. The average rim weight difference is about 10%, nearly identical to the complete wheel system weight differences.

| Carbon Rim Weight | Aluminum Rim Weight | Weight Variance |

|---|---|---|

| 430 g claimed weight

Industry Nine Solix R50 |

465 g claimed weight

Industry Nine AR25, disc |

35 g

= carbon 8% lighter |

| 370 g claimed weight

Enve SES 3.4 front rim |

425 g claimed weight

Hed Belgium R, disc |

55 g

= carbon 13% lighter |

| 348 g claimed weight

Princeton Evolution carbon climbing rim (the lightest carbon rim we can find from a reasonably well-known brand) |

389 g claimed weight

Stans Alpha 340 aluminum disc rim (the lightest aluminum rim we can find from a reasonably well-known brand) |

41 g

= carbon 11% lighter |

Read more about carbon frame weight and other challenges in Seven's white paper on carbon.

Footnotes Within Article

Footnotes for Figure 1

- "If the best and lightest carbon forks and rims are reasonably durable, carbon frames are significantly underbuilt." If riders, suppliers, and engineers agree that Enve carbon forks are reasonably durable and safe, and not stupidly overbuilt, then carbon frames must be severely underbuilt. The external surface area of a carbon frame is about 2.8 times more than a fork. In crude terms, a frame should weigh at least 2.8 times that of a fork. That's 1,200 grams. (425 g x 2.8 = 1,200 g)

- Reasonably durable carbon rims: We can approach frame weight correlation from a slightly different direction, with nearly identical results as the fork correlation. Aluminum rims exist and they are, on average 10% heavier than their carbon counterparts. Therefore, a carbon frame should be (could be) about 10% lighter than an aluminum frame. That puts the lightest carbon frames at about 1,060 grams, or 80% heavier than the industry's actual lightest frames.

- Benchmark fork: For this comparison, we use Enve's In-Route Carbon Road fork. There is no more reputable and proven fork on the market. If a supplier could build a fork lighter, they would. But they can't do that and maintain safety and a 5-year warranty.

- Fork weight not possible: If a fork were built as light as the lightest carbon frame (the Specialized Aethos at 585 grams), the fork would weigh 208 grams. The math is 585 grams for the lightest frame divided by 1,200 grams for a robust carbon frame. This is 49%. A 425-gram fork times 49% equals 208 grams.

- Carbon frame at 1,200 grams: A frame has about 280% more external surface area than a fork. If the lightest durable fork weigh 425 grams, a frame of equal durability would weigh about 1,200 grams or 280% more than the fork. This 1,200 grams is lower than it should be because a frame is a lot more complicated than a fork, as enumerated above in the fork table.

- 700-gram carbon frame: Most production performance carbon frame suppliers offer a road frame in the 700-gram range.

- 585-gram carbon frame: the lightest production performance carbon frame is the Specialized Aethos road bike. The claimed weight is 585 g without any of the hardware.

- 55%: If a frame is built with the same mission as a fork, it is likely to weigh at least 1,200 grams, as explained in footnotes 1 and 5. If a baseline carbon frame weighs 1,200 g and superlight carbon frames weigh about 700 g, that is a 45% variance. Meaning, a 700-gram frame is underbuilt by about 45%.

- 46%: As explained in footnotes 1 and 5, if 1,200 g is a reasonable baseline frame weight and the lightest frame made is 585 g (Specialized Aethos), then that frame is 54% underbuilt.

- Aluminum rim at 426 grams: This is the baseline for comparing the weight of a carbon and an aluminum rim. This rim weight is also the baseline point for comparing a lightweight performance metal frame. To reach the 426 g weight, we take three of the lightest and reputable aluminum rims and average their weights. Details in the rim table above. (The rim is a hook bead, not for a tubular.)

- Carbon rim at 383 grams: We take three of the lightest and most reputable carbon rims and average their weights. Details in the rim table above. (The rim is a hook or hookless bead, not for a tubular.)

- Titanium frame weight 1,180g (2.6 lbs): This is about the lightest titanium (and aluminum) frame weight that can still be durable and perform well. So, we use this as the benchmark for comparing metal rim weight to carbon rim weight. Because the weight difference between aluminum and carbon rims is 10%, it is reasonable to set a carbon frame baseline at 10% below a metal frame. This 10% is actually greater than it should be, as detailed in the "small elements" and "complexity of structure" rows in the frame & fork table above.

- 90%: The lightest carbon rims are 10% lighter than the lightest aluminum rims. This difference is an appropriate starting point for determining a projected carbon frame weight relative to a metal frame's weight. If a carbon frame is built with the same durability and toughness mission as a carbon rim, the frame would likely weigh 1,060 grams or more. If a baseline carbon frame weighs 1,060 g and superlight carbon frames weigh about 700 g, that is a 34% variance, therefore, compared to the benchmark carbon rim, a 700-gram frame is underbuilt by at least 32%.

- Carbon frame weight projected: Based on metal and carbon rims, the lightest carbon road frames should be about 1,060 grams, or 10% lighter than the lightest durable metal frames. Obviously, that's not the case. How is it that a carbon frame can be proportionately 32% lighter than the lightest carbon rim? It can't; carbon frames are underbuilt.

- Rim weight not possible: If a rim were built as light as the lightest carbon frame (the Specialized Aethos at 585 grams), the rim would weigh 212 grams. Projecting rim weight from a 700-gram frame, the rim would weigh 252 grams. Obviously, these are not even close to being possible. If a supplier could build a lighter carbon rim, they would. But they can't do that and maintain safety and a 5 year warranty, just as building a carbon frame much lighter than 1,100 grams is not wise (if durability is important).

- 59% (66%): 59% is the weight differential of a 700-gram carbon frame compared to the projected aluminum/titanium frame weight of 1,180 grams. 66% is the weight differential of a 700-gram carbon frame compared to the projected carbon frame weight of 1,060 grams.

- 50% (55%): 50% is the weight differential of a 585-gram carbon frame compared to the projected aluminum/titanium frame weight of 1,180 grams. 55% is the weight differential of a 585-gram carbon frame compared to the projected metal frame weight of 1,180 grams.

Footnotes for frame weight limits

- Specialized: 300 lbs.

- Trek: 300 lbs.

- Cannondale: 300 lbs.

- Enve (frames): 300 lbs.

- Giant: 275 lbs.

- Pinarello: 265 lbs.

- Canyon: 264 lbs.

- Colnago: ~250 lbs.

- Cervelo: 220 lbs.