Frame Boss Placement

tl;dr: For frame durability and longevity, Seven doesn't put water bottle style M5x.8 threaded bosses anywhere on a frame aside from the classic locations of seat tube, down tube topside, and down tube underside — all near the bottom bracket. We don't make any exceptions to this standard.

tl;dr: Water bottle bosses; we don't weld them, we rivet nut them. A lifelong frame requires bosses that can flex.

Some riders may find Seven's standard frustrating, but we have numerous engineering reasons for this rule and decades of experience informs our reasons. In short, we take riders' uninterrupted adventures as seriously as we do our warranty. In short, we're careful with hole location in our frames in order to prevent frame failure. Any hole in a frame is a likely failure point.

The managing team at Seven has punched more than 300,000 water bottle bosses and holes in well over thirty years of building 70,000 frames in the United States. We've tried everything. We've seen firsthand all the ways it can go wrong in the long run.

We really do want to build lifetime bikes. Drilling holes is one of the many ways to cut short a frameset's life.

What Problem Are We Trying To Solve?

Riders use mounts for multiple purposes, so it's difficult to generalize. However, the most common requests are top tube bag mounts and frame bag mounts. Why would a rider want mounts rather than straps?

Stabilization

Frame mounts are counterproductive for two reasons:

- Top tube bag floppiness, specifically, is not due to inadequate bag connection to the top tube; it's due to the top-heavy nature of the bag. To avoid beagle ear flop, the bag needs anchoring at the head tube — the one place where a frame mount is not possible. Fortunately, there are solutions for this, which are usually unnecessary, but they are available for riders who overstuff their top tube bags. Frame bags have the same flop-slack issue to a lesser extent.

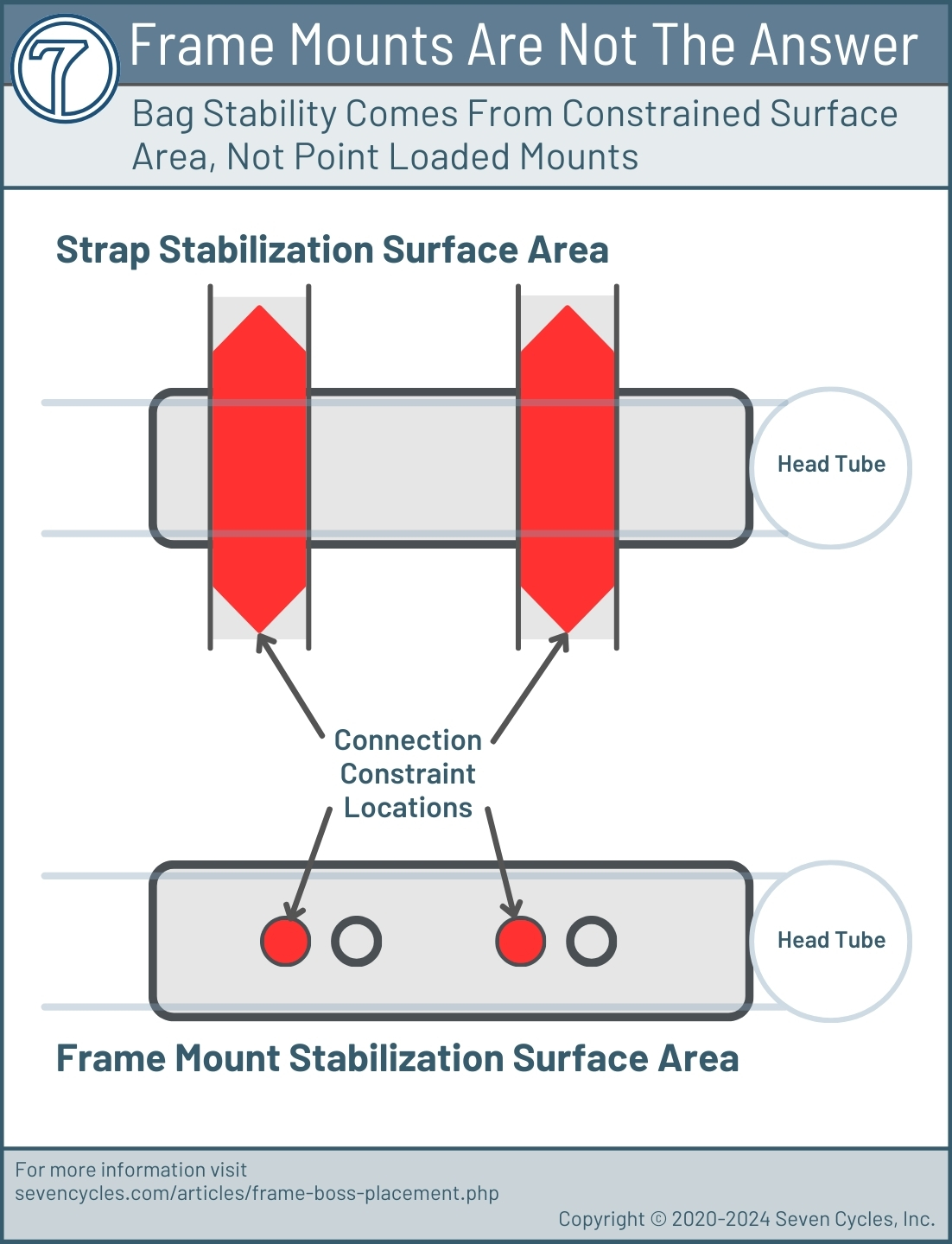

- Frame mounts are single-point connections. Conversely, bag straps generally stabilize from the outside edges or lower face of the bag. This provides many times greater surface area interface between bag and frame tube and, therefore, stability.

Avoiding Scuffs And Scratches

This concern is irrelevant to titanium frames; any scratch is cosmetic and removable through a quick refinish. Conversely, for carbon and painted frames, damaging the surface is a serious concern, so frame mounts might seem like a good solution. However, the paint will still get damaged when attached to frame mounts. Protecting paint is better accomplished through the application of clear frame protectors.

Two And A Half Issues

From a rider perspective there are a few issues to contend with. From a manufacturing perspective, there are a lot more issues. Here, we frame the rider's interests.

Boss Bridge

A properly designed water bottle cage has a bridge between the bosses that serves two purposes. First, it stiffens the bosses locally, and second, and more important, it disperses the load between the bosses; neither boss can flex or deform independently. Frame bags have no stiffening or load dispersion elements. Each boss has to deal with load, deflection, and deformation on its own, supported only by a very thin wall tube.

Boss Abuse

Boss damage or frame damage due to boss abuse is one of the most common frame issues we see nowadays. This situation is a modern bike problem. It's become an issues over the past decade as adventure riding and self-supported exploration have become popular. This type of riding often requires frame bags, oversized cages, tool containers, and other heavy duty items that the average water bottle mount was not expecting.

Corrosion Issues

Another issue with frame bags and rivet nuts is galvanic corrosion. Bags get wet and often live permanently on frames. When wet and in contact with titanium, stainless steel or aluminum rivet nut corrode over time. Eventually, the bolt and rivet nut loosen and eventually dislodge. We've seen this happen too many times.

Alternatives to "holes" everywhere?

We at Seven love adventure riding and bikepacking. Seven customizes bikes for this very purpose every day. There seems to be a dichotomy between the adventure bikes we live to build and our conservative position on boss placement.

It's really not that big of a deal. Frame bags and top tube bags are all designed to work with non-holed frames.

Stability Without Bolts And Bosses

A number of solutions exist, from grip tape to mechanical stabilizers. Bikepacking.com recommends using a bag stabilizer that connects to the fork top cap.

Futureproof For 70

One of the functional day-to-day downsides of fixed bag mounts is that over time, as you experiment with bag placement, initial bolt locations may not be ideal. Additionally, each time you acquire a new bag, odds are the bolt holes will be in different places. Bikepacking.com provides a current list of more than 70 top tube bags.

So Many Rules

When you're planning your Seven, here are the basic rules that Seven follows. These rules ensure we can offer a lifetime warranty.

- Location limits: Bottle or frame mounts can only be in the two standard water bottle locations: Seat tube and down tube — both near the bottom bracket.

- 1.5 rule: No single boss can see a use load of more than 24 ounces or 1.5 pounds.

- Connected boss rule: The water bottle cage has to span the distance between the two bosses with a rigid truss to connect the two bosses. This significantly increases the stiffness of each boss and ensures a lifetime of use. No boss can be employed singularly. Bosses always have to be used in pairs or triplets for some cage designs.

We have a lot of other boss rules but they are proprietary and for internal use only.

Joe Cruz has done more bikepacking and remote adventures than just about anyone. It's critical that his equipment holds up. Follow Joe's lead, and don't drill holes all over your frame, and don't ask Seven, too, either. Any bag or bottle you see on Joe's bike that's not in Seven's standard bottle locations is either strapped or taped.

Experience

Why are we confident in our boss rules? We learned through brute force and hundreds of thousands of hours.

- Experience: Our founding engineer has been working in the industry for nearly 40 years; about two generations of framebuilders. We've seen a lot over that time. We watch the cyclical nature of "progress." New builders typically make the same mistakes that the last generation of builders learned but then forgot.

- Quantity: Seven has built more than 35,000 bikes. All custom and handmade. This custom aspect is important because it provides us with unique depth and breadth of design feedback. In addition to that, our founders handbuilt another 40,000 frames before Seven was even a concept. We've seen all the mistakes. We've made most of them. We try not to repeat them.

- Testing: We have an in-house fatigue tester. We've tested numerous boss configurations; only rivet nut bosses pass the tests.

- Reputation: We want to protect our reputation. We're not perfect by any means, but we try real hard to learn from our building mistakes. We don't chase trends or fads. We're not trying to sell "one more bike." Our founders have been in the industry for four decades. We want to be here for another four decades. The only way to do that is to take this stuff seriously. The bike world is littered with bike builder flashes in the pan. This happens when new builders do untested stuff that fails.

Frequently Asked Questions

Why not use welded bosses? They're way stronger than a rivet, right?

No. It is reasonable to assume that a welded structure would be better than a threaded rivet. Unfortunately, we have a lot of experience with welded bosses. It doesn't end well. The engineering is surprisingly complicated. The weldment creates a hard spot in the very thin tube. This creates a stress riser that eventually fails. A rivet nut, by design, is able to flex with the tube. Some flex is good at reducing stress and eliminating the stress riser.

One of the classic errors new titanium builders make is welding in bosses. If that builder survives for a handful of years and builds 100-plus frames a season, they typically stop offer welded bosses.

What about Seven's internal housing and wire routing? Isn't that just holes in tubes, too?

No, not just holes. These are reinforced ports that have layers of machined material protecting the internal. Equally important, there's no load bouncing around and trying to extract the weldment from the frame (as is true with a frame bag, top tube bag, etc.)

Company X offers frame bag mounts and a lifetime warranty.

Did you know that bicycle frame manufacturers' warranties do not cover fatigue failure? Most mount failures could be considered fatigue failures. At least, it can be difficult to prove that a mount failure was not caused by fatigue.

Are you certain the frame has a lifetime warranty? Many well-regarded companies no longer offer lifetime warranties. Here are a few examples of gravel frame warranties as of 2023. (We're not throwing shade on these companies; these are just a few examples of how the industry has changed in the past decade.)

- Colnago C68 Gravel: 2-year warranty

- Pinarello Grevil F7: 2-year warranty

- Open Upper: 3 year warranty

- BMC Urs: 3-year warranty

- Enve Mog: 5-year warranty

- Canyon Grizl CF SLX 8: 6-year warranty

Ignoring the definition of warranty for a moment, does the framebuilder have more than a decade of framebuilding experience? Have they built thousands of frames with bag mounts (not just water bottle mounts)? Have they never had a frame failure instigated at one of these mounts? Do they do in-house fatigue testing or even subcontracted fatigue testing? If you know of a company that can answer "Yes" to even one of these questions and offers bag mounts, we'd like to see it.

For the record, Seven answers yes to all of these questions.