Last night Jake and I left work a bit early and headed west to Lancaster to compete in the Midnight Ride of Cyclocross. This fast and fun mid-week race is in its second season and after hearing the rave reviews from last year I put it on my calendar as “can’t miss.” The Midnight Ride follows a similar course to November’s MRC race, but in the reverse direction. Since it’s still September, the course was dry and fast and the reverse direction offers less climbing and off camber turning than it’s November counterpart. Announcer Richard Fries was on hand for the event, which always makes things more exciting, and as he repeated multiple times throughout the evening, this race is the kickoff to what is now known in New England cross as “Holy Week.”

Racing as a beginner amateur and working at Seven, I’m in a great position for success. I have friendly relationships with some top Pro racers who have raced on the very same courses that I now compete on and they willingly offer up advice on things like tire selection. I ran into Mike Broderick and Mary McConneloug at Cross-Vegas last week and Mike gave me some tips on what to run for the Holy Week races. I heeded his advice and it paid off in spades. The treads that I had chosen were fast on the gravel and pavement and hooked up just well enough in the grass and loose loamy corners that I was able to walk that fine line that exists between speed and control. Line selection, not tire selection, would be the only fault in my race.

I’ve raced enough at this point that I am starting to get first row call-up and for this race I lined up one spot from the outside with a clear view of the first turn a few hundred yards ahead. At the whistle I jumped out in front and my first four of five pedal strokes put me out in front with a fair gap on the field. I had taken the hole shot, and it was suddenly my race to lose.

Having never been in this position before in any sort of bike race, I did my best to stay calm and just rode my ass off. From what I’ve been told I actually put a sizable gap on the field and held it until my worst case scenario presented itself – a crash in a hard 180 degree turn on loose gravel. I got up faster than imaginable and got back on the bike, but after a couple more turns I lost the lead.

As we wove through the course and over the barriers I held onto second position for dear life and started to hear Richard announcing that the 14-year-old in the group was gaining on the leaders. I held second place for about a lap until the leader missed a turn in the woodchips and slid out – I was back in front. For the next two laps I led this group of men and boys through the twists and turns of the Midnight Ride course and listened to Richard’ words about what it might mean to our egos to lose to a 14 year old.

He also seemed to give Jake’s single-speed a shout out every time he passed through the start finish area. When I finally saw the lead slip away for good, it was a newbie to cross, not a kid whose brothers have been notorious for cleaning up in the men’s field as juniors, who took it away from me. I kept fighting and rode most of the last three laps in the 5th position and watched another young and new-to-cross racer, who had fought from the back row past about 65 other riders to take the lead with two to go.

When he went by the leaders he rode off in front with ease at a pace that none of us could match. I was cooked, and hanging on by a thread, dry mouth, blurred vision, etc., when I heard a friend yell “Joe! Hurt!” Oh, yeah, I thought, this is not supposed to be easy, you have to hurt to win, there are no two ways about it. I kicked it back in but unknowingly was making it easy for the rider behind me. He was drafting me around the course and saving energy for a move in the last grass section before the pavement to the finish.

I feared if I let him around me so that we could work together that I would not be able to hang on, so my best bet was to keep him behind. It seemed to work, but in the end he made a move and went around me just as we came up on that speedy young teen who had finally run out of gas with just a few turns to go.

The result of these place changes left me squarely in 5th place, another top 5 finish in what has been a great start to my season. A few more like this and the heckles along the course, hopefully, will be encouraging me to “cat up” into the 3’s, a place where many a family man can spend the bulk of his bike racing career.

Post-race, Jake and I grabbed a beer and heckled some friends as they suffered much in the same way that we just had, and then cheered on Mo Bruno Roy as she rocketed around this drag strip with apparent ease. I picked up some tire tips from her husband and pit crew, Matt Roy, and he showed me some new treads that they are trying out for this season. It’s good to be an amateur, it’s great to get the inside line on tech tips from the pros, and it’s amazing to have the opportunity to ride and race on a bike that is just like the pros race yet uniquely built for me.

– Joe W.

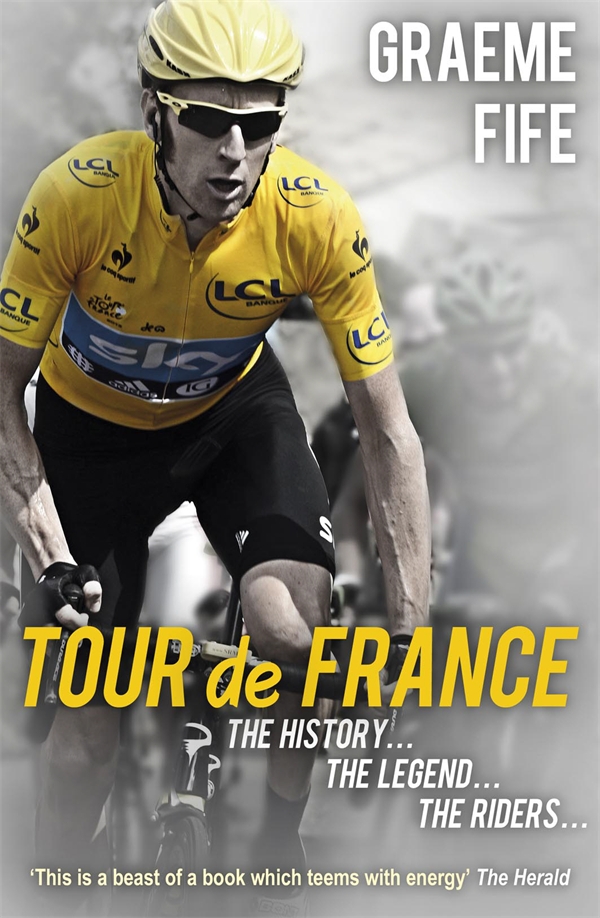

Image: Matt Pacocha, Bike Radar.