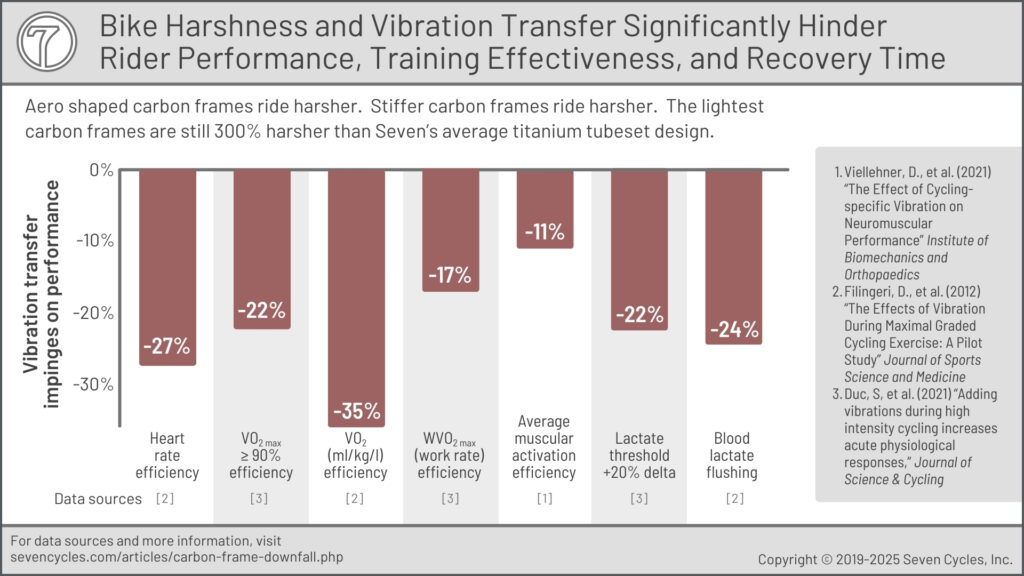

Without exception, carbon frames ride harsher than well-designed titanium frames. A harsh frame transmits more vibration to the rider. Vibration requires the rider to expend energy to control the bike. This significant energy expenditure is reflected in increased heart rate, higher VO2 at a given wattage output, and higher blood lactate during and after efforts.

Read the full recovery article.

The point is that if you ride carbon, you’re beating up your body and slowing your recovery time. You’re also reducing your work capacity and endurance. (Keep in mind that a harsh riding frame is not the same as a stiff frame. Read Seven’s carbon white paper for a full explanation of this seeming contradiction.)

All of this is often referred to as rider durability, and it is the latest frontier in professional cycling‘s ongoing pursuit of improved performance. Tadej Pogačar exemplifies a rider with significant durability.

Seven’s white paper on carbon’s shortcomings places the vibration issues within a holistic framework. In summary, greater vibration yields lower training effectiveness.

We use third-party data to explain the issues. The figure below illustrates several vibration problems. Additionally, to describe the obstacle, we’ve included quotations from some relevant sports and medical journals on the topic.

“Vibration increased oxygen uptake and heart rate. […] heart rate supports the existence of an elevated metabolic demand. This is consistent with previous studies that reported a 7% increase in heart rate and an increase in oxygen consumption. […] The findings align with other studies of full-body vibration or high exercise intensities that report increased oxygen uptake.” — The Effect of Cycling-specific Vibration on Neuromuscular Performance, Medicine & Science in Sports & Exercise

“Vibration as an external stimulus produced a significantly greater and quicker energetic demand to the body and thus it was perceived as a greater workload.” — The Effects of Vibration During Maximal Graded Cycling Exercise: A Pilot Study, Journal of Sports Science & Medicine

“[T]ime above 90% of V̇O2max and mean V̇O2 during HIT work intervals were higher in vibration session than traditional [no vibration] session. This may at least partly be due to the increased muscle activation in lower and upper limbs observed.” — Adding vibrations during high intensity cycling increases acute physiological responses, Journal of Science & Cycling

“[I]ncreased acidosis generated during the Vib trial might be not the only cause of the anticipated skeletal muscle fatigue. […] relatively long exposure to Vib, generally more than 7 min leads to a decreased power and force production. Authors reported that an acute reduction in maximal voluntary knee extension force and a depression of the voluntary activation of the leg extensor muscles up to 180 min after an exercise bout were obtained in participants exercising on a vibrating platform. […] vibration can negatively affect cycling performance in terms of exercise duration when exercising at a constant submaximal workload.” — The Effects of Vibration During Maximal Graded Cycling Exercise: A Pilot Study, Journal of Sports Science & Medicine

“The experimental hypothesis stated that the VCE [vibration cycling exercise] […] would have produced a significant variation in the monitored physiological parameters compared to the effects of traditional cycling. The results of this study confirm this hypothesis in terms of the increased energetic demand generated by the Vib [vibration] exposure.” — The Effects of Vibration During Maximal Graded Cycling Exercise: A Pilot Study, Journal of Sports Science & Medicine