Seven’s Rider-Ready gravel bikes cover all the dirt-centric bases, with 14 models. That number is just for frame types; it doesn’t include parts kits, cockpits, or wheelset options.

Fortunately, deciding which is right for you is simple.

Generally, riders define gravel bikes by a few attributes:

- Maximum tire size, minimum tire size

- Gearing and range

- Frame and fork mounts, cargo capability

- Frameset geometry, handling

- Tubeset, ride characteristics

The two most commonly researched attributes are tire size (how big can the bike go?) and gearing (does the bike have the right range for how I ride?).

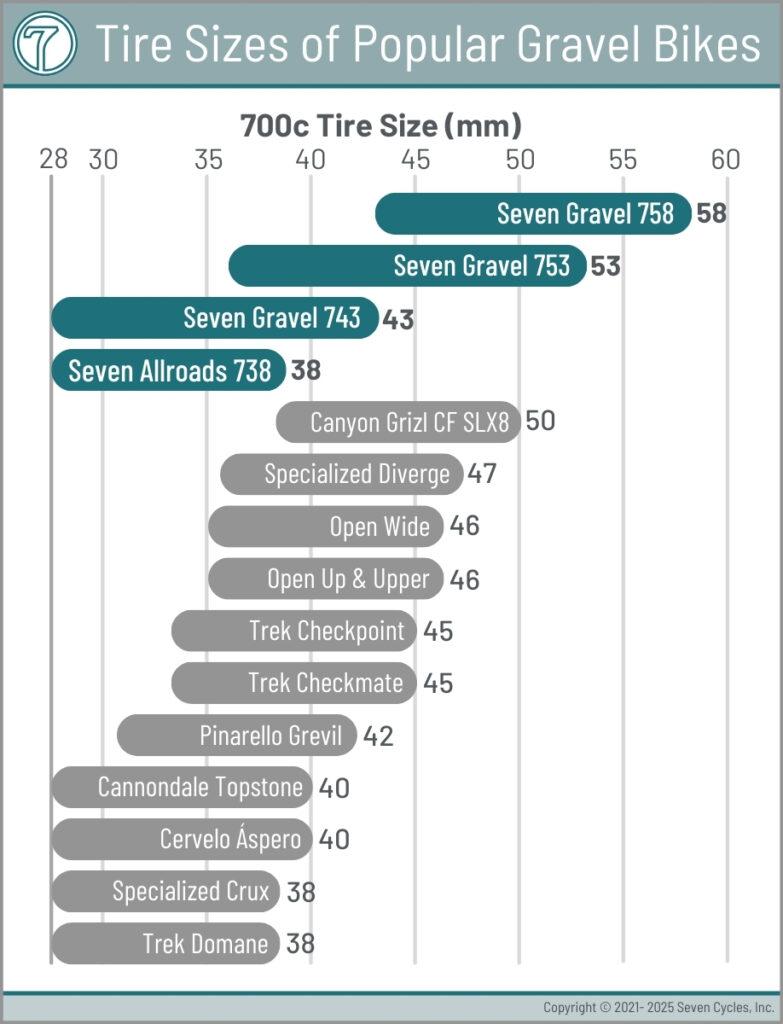

Seven Rider-Ready bikes have a greater maximum tire size selection than any stock bike brand. We also offer the most gear range options of any brand. For example, our Gravel 743 model has 15 kits to choose from, 19 wheelset options, and other options and upgrades. You’ll find the perfect parts combination for your riding.

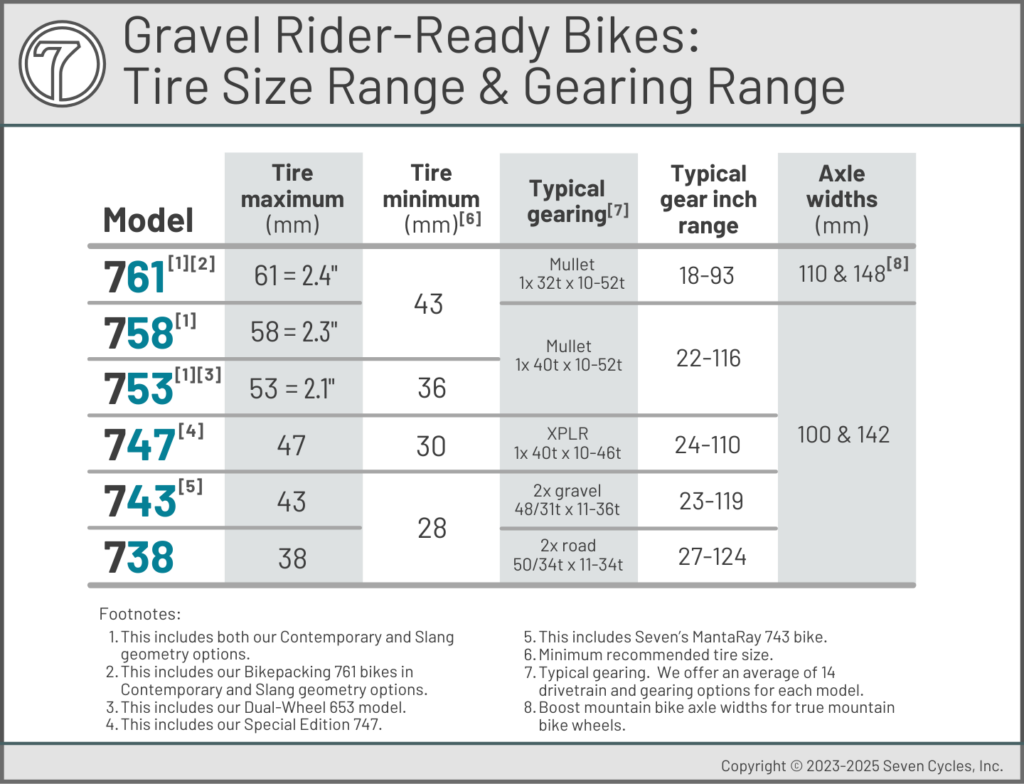

Here’s Seven’s current gravel Rider-Ready bike lineup by tire size range and gearing range. We’ve also included wheel axle widths, an unusual focus for gravel bikes, but it’s becoming useful because of the recent interest in larger tires. Our Gravel 761 and 761s (Slang geometry) are designed with boost axle spacing for a stronger, stouter wheel that can handle rougher terrain. The 761 and 761s are true mountain bikes with drop bars.

We offer six maximum tire sizes across our 14 gravel Rider-Ready models.

Why so many tire sizes?

As the rear tire gets larger, the chainstays must get longer, and optimal gearing tends to get lower.

The more specifically we can offer your ideal maximum tire width and gearing, the shorter we can make the chainstays.

Chainstay Lengths

No one wants chainstays longer than necessary. [1] There’s no reason to have longer stays if you don’t want a larger tire. Choose your max tire from our six offerings, along with your preferred gearing, and you’ll have a bike with optimal handling geometry.

Max-Min Tire Width Range

Equally important, when the maximum tire size changes, so too does the minimum tire size. Most bike specs are silent regarding recommended minimum tire width.

We find that for many riders, the min-max range is as important as the maximum tire size. Many riders are dual-wheel riding these days – having a wheelset for gravel riding and a second wheelset for road riding. So, knowing the recommended minimum tire size may influence your purchase decision.

Having a balance of tire size range is often the ideal. For example, the Gravel 747 is currently Seven’s most popular bike for tire range. The 747 is an excellent 30 mm tire road bike, and at the wide tire end of the spectrum, the 47 mm tire is nearly a mountain bike tire. It’s a combination that’s difficult to beat.

Gearing

In another example, our popular Gravel 758 gets you to 29 x 2.3″ tires (700 x 58 mm). On paper, the 758 is similar to the Gravel 761. However, there are two important differences: 1) Hub spacing and 2) gearing. These might seem like minor distinctions, but for some riders, it’s the difference between perfection and just another gravel bike that missed the mark.

The 761 is a true mountain bike with drop bars (and frameset geometry designed for drops). The 758 is capable of the same trails but is also designed for gravel gearing and has gravel hub spacing. This gravel axle spacing provides more wheel options, but they are not as tough and stiff as mountain bike wheels. Of course, everything is relative. Our 758 is tougher than any other gravel bike on the market. It’ll hold up; don’t worry.

Each of our gravel models, including our current special edition 747 and our MantaRay 743, has specific purposes. One of which will be ideal for you.

Life is short. Choose your own adventure, bike, and ride.

Footnotes:

- Longer chainstays are not a bad thing. Riders tend to focus on short chainstays. The shorter, the better, right? In reality, after designing 35,000 bikes and doing endless testing, Seven knows that shorter stays are almost never the answer to improved handling. Regardless, if you want the shortest stays possible, Seven offers our chopped chainstay design that provides among the shortest chainstays possible for any tire size.