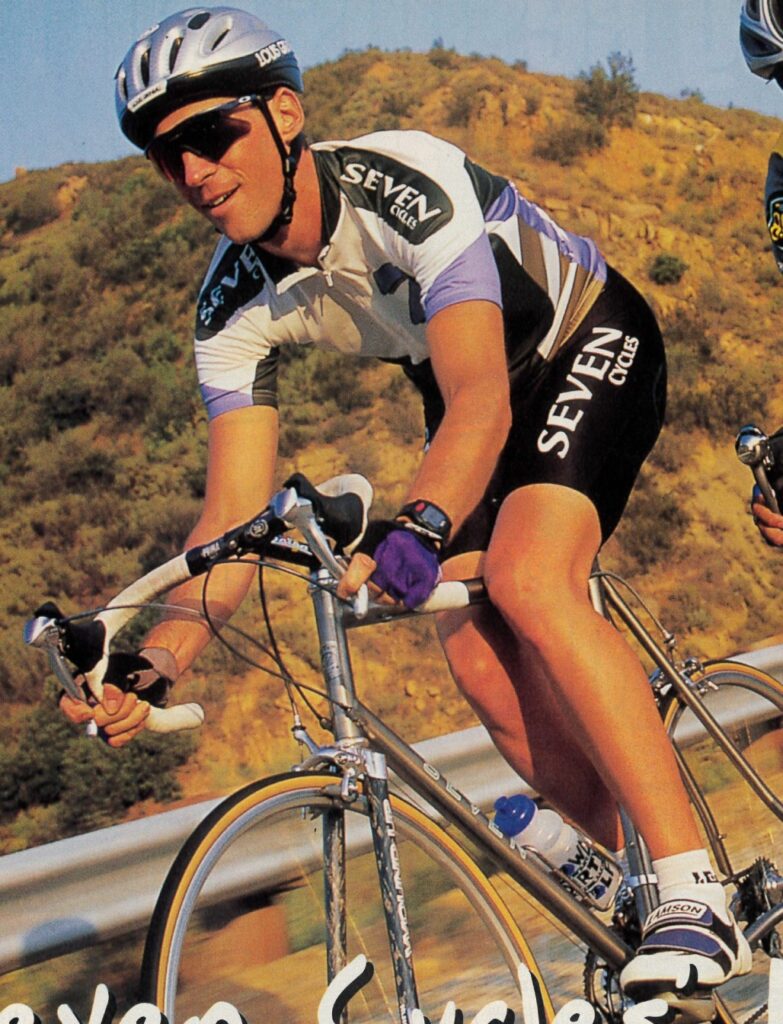

Patrick Brady & John Lewis Talk Seven Bikes on the Cycling Independent Podcast

It’s a good conversation. Check out the Paceline Podcast 409.

As is always the case with Robot and Padraig, they had a great conversation that covered a lot of ground. During one segment, they talked about the bike they’ve each spent the most time riding over the years. To both their surprise and Seven’s, both have ridden Sevens more than any other bike.

Here are some Seven selfish highlights.

Some of what Robot (John Lewis) said about his Axiom SL:

“It’s simply the best bike I’ve ever owned. It is a whisper over pavement. It is a telepathic extension of my body. Everything I want a bike to be and nothing I don’t.”

“I thought I understood what [Seven] did and why it was good. [Within the first] maybe 50 yards, everything was perfect. You feel that in your body.”

“Everything was more perfect with this bike, right out of the assembly stand, than any other bike I’d ever thrown a leg over before.”

“It is something else. I knew intellectually all the information, but to feel it in my body, I was gobsmacked. It’s all true.”

“It was my everything bike for a while. I rode D2R2 on it.”

“Getting a Seven was like going through the wardrobe into Narnia. Like moving from normal everyday life into another realm.”

“It was like Spiderman, the first time he’s clinging to the side of a building and looks down. It was that sort of like, oh, this is a new reality.”

Some of what Padraig (Patrick Brady) said about his Axiom SL:

“The best bike I’ve ever ridden.”

“The Seven was the yardstick by which I measured other bikes. No bike ever came close to measuring up.”

“A fair amount of stiffness for a Ti frame. Stiffness is often something that gets underdone with titanium.”

“Another thing the Axiom taught me was the value of a stiff top tube. Too flexible a top tube hurts the way the bike tracks and turns.”

“On occasions when someone would ask to check out my bike, what I heard repeatedly is they loved how calm the bike was at speed, and yet it always turned without hesitation.”

“I could race any crit against people on more aggressive bikes.”

They both have owned many bikes over the years. To have them both ride their Sevens the most means so much.

This is why we build bikes every day, all day.

Thank you both!