The first bike I ever built was a Trek 800 mountain bike at Alpha-Lo Bicycles in Wallingford, CT when I was in 6th grade. I had applied to work at the bike shop weeks earlier, even though I had few skills in the realm of sales, merchandising, or mechanics, and yet they hired me anyway. Chalk it up to the sweetheart of an owner, and my obvious love for his store.

I worked on the weekends, and though I doubt I provided $20 of value, that’s what I was paid. Keeping the shop presentable was my number one priority, which sounds lame, but I couldn’t get enough of it. I took great pride in shifting the bikes to the big ring, pulling products to the front of the shelves, and vacuuming the floor. When the shop was clean, George, Aaron, and Matt all pitched in to help me learn the basics of bike mechanics.

The shop wasn’t enormous, but it felt like we hand an endless array of entry level mountain bikes to assemble. Building these bikes would become my second responsibility. At the time, I could operate a quick release and fix a flat, but that was the extent of my skills. I was a clean slate. The learning curve was steep, and I wasn’t the quickest learner, but the shop guys were incredible teachers, celebrating victories when I had them, and understanding when I failed. They’d gather round to inspect, coach, joke, mock, and help whenever I was stuck. They’d pull up stools and watch, or shout out advice from afar.

Life was good. What I learned at that shop wasn’t a mastery of bike mechanics, something I’m still searching for, but a love of the bike build and the fanfare that goes with it.

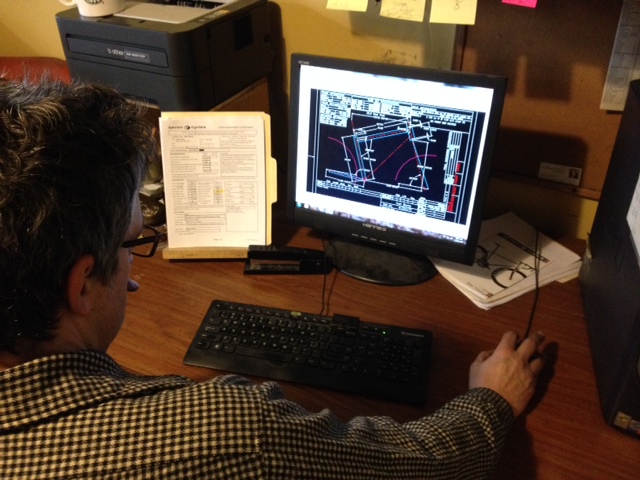

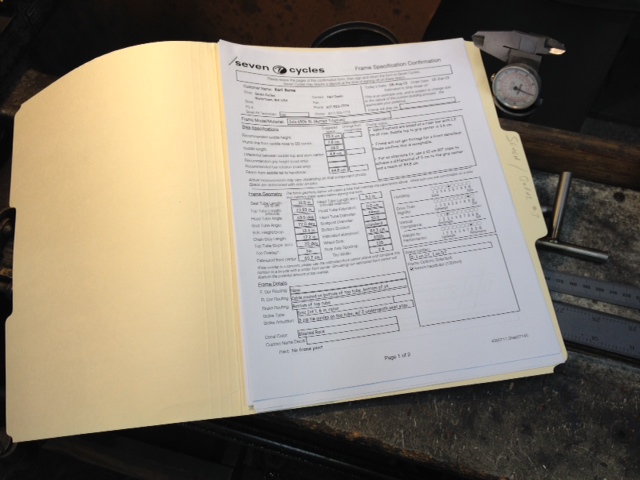

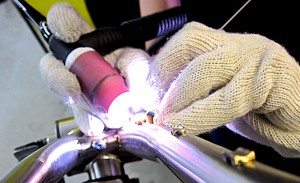

At Seven Cycles, we have a bike stand and work shop just beyond our bike commuter lot. Low on bells and whistles, but high on character, it has all of the essential tools to transform a frame into a complete bike, a well worn work bench, recycling bins, a vice, shelves, rags, a drawer of miscellaneous parts, and stools. Whenever a bike is being built, whether it be a new bike for a magazine review, or someone’s old beat up commuter, people gather. Opinions are voiced, jokes cracked. The stools fill with spectators. Assistance is provided, wanted or not. Should the build happen after work, the crowd grows along with the laughter.

The technology has changed, as have the tools, but the fanfare of a bike build today is no different than it was when I was a kid. I wouldn’t want it any other way, and I can’t think of a better place to build my new Sola.