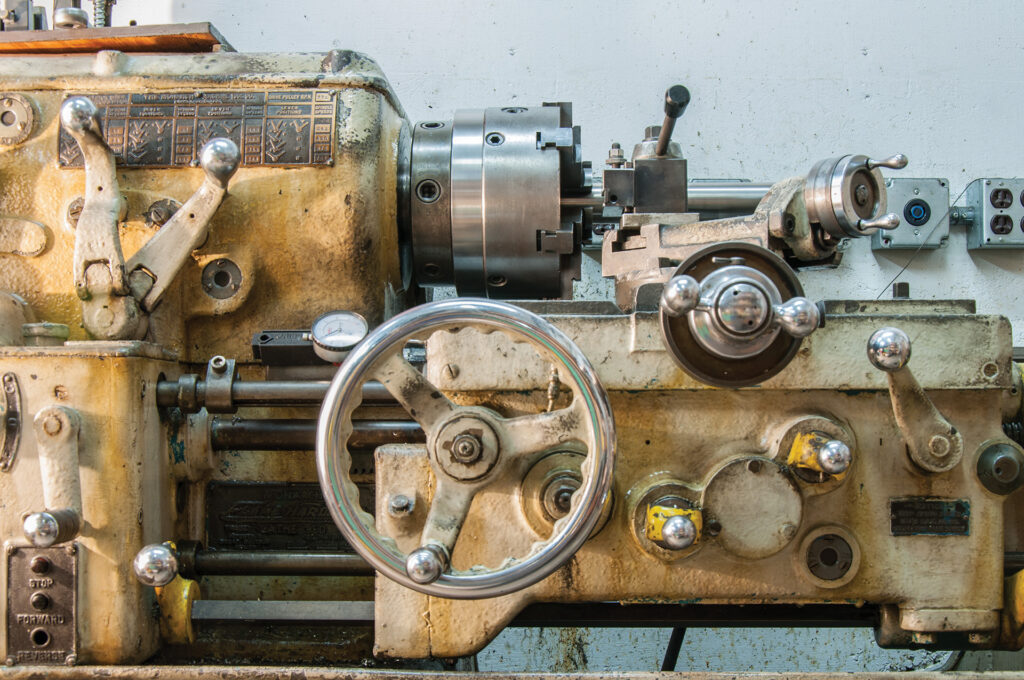

This lathe, built in 1942, came from a local trade school who were upgrading their equipment. We use it to repair parts for the other machines on the shop floor as well as to build fixtures that will be used to streamline the production process.

Author: Seven

On Framebuilding: Part Four – Paint

Painted frames get prepped, then hung on the rack just outside the odd looking, seemingly out of place, paint booth. Its silver walls look like nothing else in the building. A sign hangs above the door that reads “time machine.”

Continue reading “On Framebuilding: Part Four – Paint”

On Framebuilding: Part Three – Final Machining and Finishing

Final machining completes the frame, making it ready to assemble into a fully functioning bike. The head tube, ever so slightly distorted from the heat of the welding torch, is faced and reamed on a vintage, Massachusetts-made lathe.

The bottom bracket, still just a thick walled tube at this point, is threaded and machined in the CNC, the largest machine in the building. Seat tube notches get cut, and carbon fiber tubes are fitted into the frame if we are building a titanium/carbon model.

Continue reading “On Framebuilding: Part Three – Final Machining and Finishing”

On Framebuilding: Part Two: Welding

Six tables form the circumference of the welding area. Unlike the back and forth, on-their-feet movement of the machinists, welders work more like laboratory scientists. Instead of operating multiple, massive machines all at once, they set up shop on a broad metal desk with all of their tools within arm’s reach. A torch, argon purge hose, different lengths and widths of filler rod, metal blocks that serve as heat sinks, clamps, and of course the welding mask are all there.

Continue reading “On Framebuilding: Part Two: Welding”

On Framebuilding: Part One – Machining

Collated in an ordinary manila folder are the details of your new bike. Body measurements, preliminary sketches, notes, revisions, and final drafts are all there, as is the signed confirmation form perched right on top. To non-cyclists, a loose sheaf of papers like this might not get the blood flowing, but it works for us, and probably does for you, too.

This paperwork, after all, is the blueprint to a bike that has never been seen before, a bike designed to make your favorite rides even better, a bike specifically for you.

Continue reading “On Framebuilding: Part One – Machining”