Seven's 622 Carbon Framebuilding Platform

Carbon-titanium frames are stronger for longer

Seven's carbon-titanium frame designs address the primary weaknesses of modern monocoque-style carbon frames. Seven's designs lose no stiffness performance over time, are ten times more damage tolerant, have more than five times higher fatigue life, mimic the best ride characteristics of titanium, and will fit and perform better than any stock bike.

Learn about our carbon-titanium bike models.

Warning: This page is dense and technical. Only read it if you want to understand the shortcomings of contemporary carbon frames and how Seven mitigates these issues with our 622 carbon fabrication processes.

What is Seven's 622 Carbon Frame Platform?

The common aspect of the PRO and CT models is the 622 platform. This is the base from which we design each model. 622 stands for carbon and titanium. (6 is carbon's atomic number. 22 is titanium's atomic number.)

The Five Primary Weaknesses Of Modern Carbon Fiber Frames

This information isn't on any carbon bike brand's website. There's no incentive for anyone to explain the severe shortcomings of modern monocoque-style carbon frames. Seven, having built frames using every method and can offer carbon frames of any manufacture style, has no bias of material or process. We've built thousands of full carbon frames over the years and consulted for some of the best carbon framebuilders.

While the following is not on any carbon brand website, all of this information is publicly available in hundreds of peer-reviewed research papers.

Here are the key problems with most carbon fiber frames:

- Resin has no strength and yet is 50% of a carbon frame's volume.

- Stiffness decay: As the resin microcracks, the frame becomes more and more flexible over a relatively short time.

- Requirement of stiffness: Because the resin is weak, if flex is allowed, the tube fails much faster. Stiffness slows the failure of the structure.

- Abrasion and impact: Ride Unbound in muddy conditions, and your carbon frame will probably be unrideable due to wear at the chainstay and seat stays. Even in the driest of climates, any impact, crash, or dropped wrench could result in the need for replacement. Read the popular Condition 1 warranty disclaimer for a harsh example of carbon's frailty.

- Hidden hand layup, along with bladder molding, results in imperfections and voids. Rarely are the defects visible. These issues lead to unpredictable frame failure.

Carbon Weakness 1: Resin

Poor service life and degrading frame stiffness are two problems caused by resin.

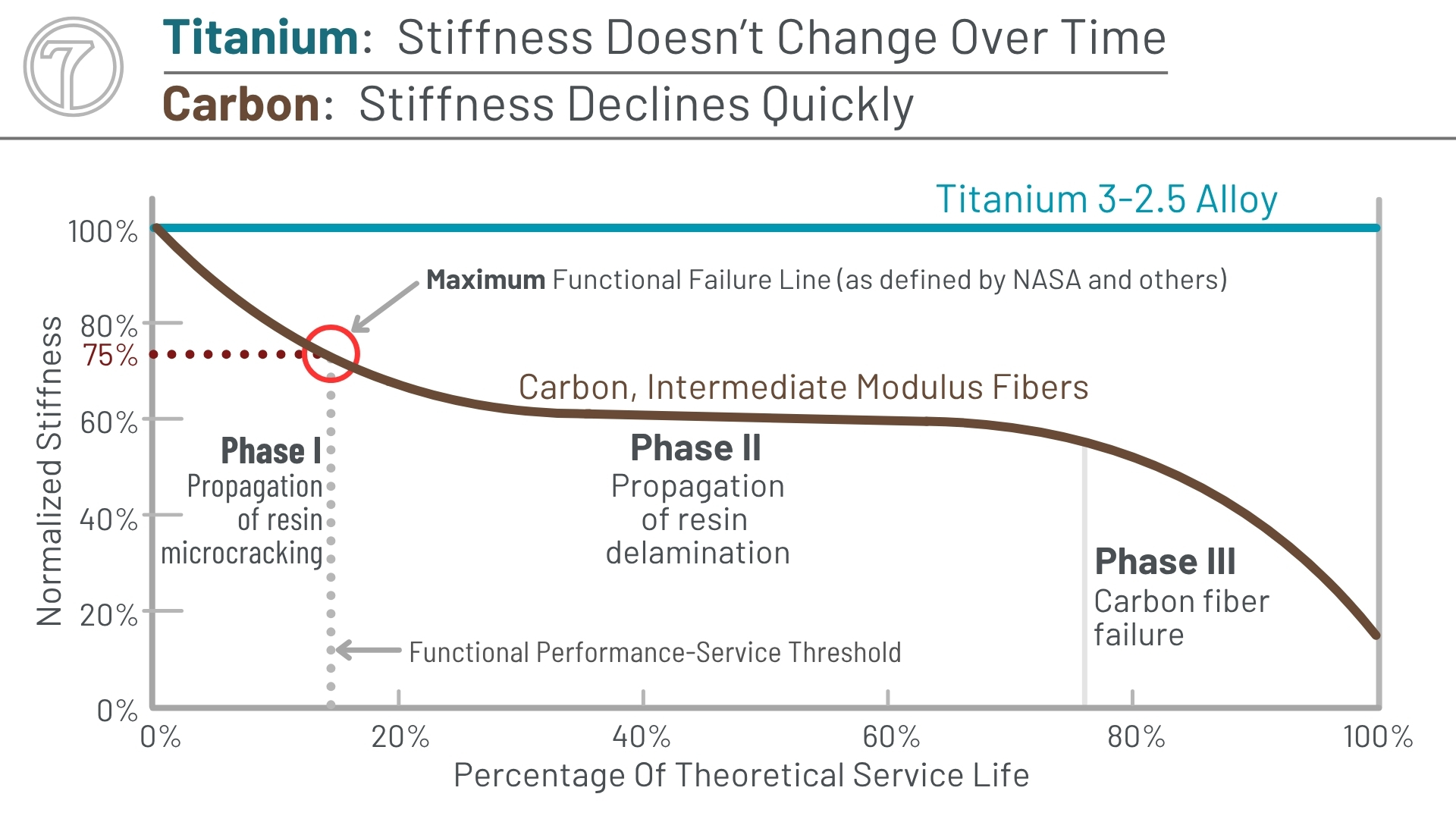

Resin is the glue that holds together carbon fibers for framebuilding. The resin has no meaningful strength. It has 20% fatigue strength compared to aluminum 6061 T6. (19 MPa vs 95 MPa.) It has 2% fatigue strength of intermediate modulus carbon fiber. (19 MPa vs 980 MPa.) Resin accounts for 50% of the total volume of a carbon fiber frame. It begins to microcrack immediately upon bending and deflection. Over time, these microcracks become fiber delamination points, which lead the carbon fibers to fail. As shown in Figure 1, this three-phase failure mode is well documented and understood by any carbon engineer.

Carbon Weakness 2: Stiffness Decay

Bike handling and predictability deteriorate over time as a carbon frame's stiffness fails.

Carbon fiber laminates have an unusual stiffness decline compared to monolithic metals. As shown in Figure 1, a carbon frame becomes more flexible with every use. Metal frames exhibit zero modulus (stiffness) decline over time. Figure 1 uses titanium as an example. Carbon frame stiffness decline is caused by the resin's inability to hold the carbon fibers together.

Carbon Weakness 3: Requirement of Stiffness

Poor handling and control are hallmarks of a frame that has the wrong kind of stiffness. A harsh ride and feeling isolated from the terrain are also common issues of a frame that's wrongly stiff.

As Figure 1 illustrates, if a carbon structure is allowed to flex it will become ever more flexible until it fails. Resin's poor properties are, once again, the problem. Therefore, carbon frame designers are likely to maximize frame stiffness, not for performance but to reach a proscribed service life.

"But, stiffness sounds like a good thing. Doesn't it make the bike perform better and be more responsive?"

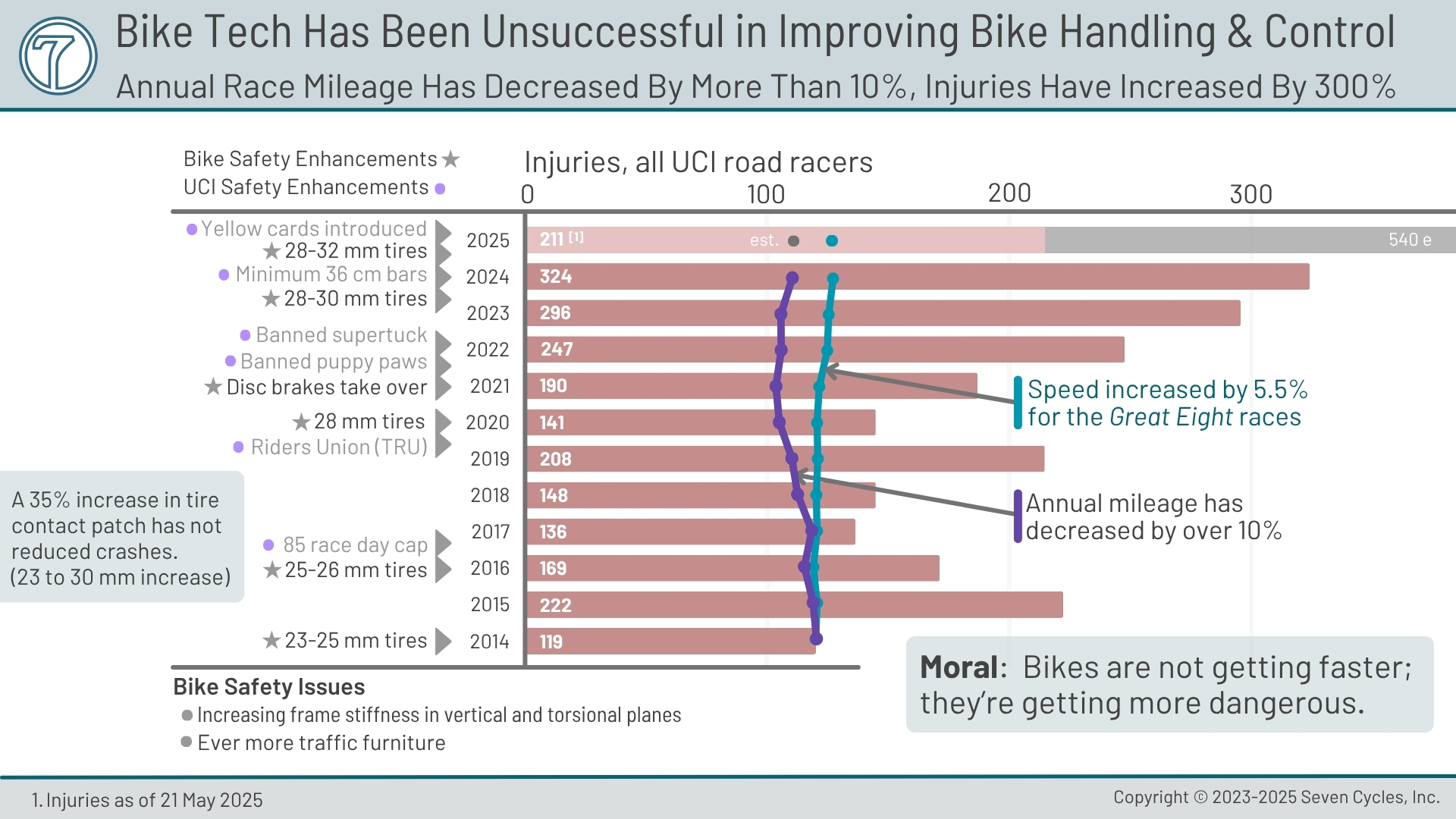

Stiffness applied strategically benefits performance. However, generalized stiffness in all planes of the frameset is problematic. Bike control is Seven's biggest concern when frame stiffness is imbalanced. For example, as Figure 2 shows, over the past decade, injuries from crashes at the UCI World Tour level have increased by 300% while almost all aspects of the racing landscape have improved rider safety. Read our article, "More Crashes. The Cost of Progress?" for a detailed evaluation of the causal link between frame "technology" and the substantial increase in crashes over the past five years. The article proves that crash problems are not caused by the tropes of increasing speed, a fuller racing calendar, longer races, traffic furniture, or "all out" racing.

Carbon Weakness 4: Abrasion and Impact

Frame failure and unpredictable service life result from abrasion and poor impact strength.

Carbon is abysmal on the abrasion and toughness front. Crash once; a carbon frame is likely to be totaled either through pavement/grave abrasion or impact damage. Read the "Condition 1" care instructions for a good summary of carbon's fragility.

Ride in thick mud conditions, and that mud on tires is likely to wear through the frame's chainstays or seat stays. Drop a chain and start chewing through the chainstays or bottom bracket shell. So many issues to keep an eye on.

Anything strapped or bolted to a frameset is a likely abrasion spot. A top tube bag, frame bag, bar bag — anything that shakes in place or slides along the carbon will wear through it. And, there's often not much there to wear away. The lightest carbon frames are as thin as 0.025" (about eight sheets of paper).

Sometimes, impact damage is not visible. It's easy to delaminate the resin from carbon without noticing. The damage is there and will become apparent at some point. Be safe.

Carbon Weakness 5: Hidden hand Layup

Frame failure and unpredictable service life are problems caused by hand layup.

Every well-made frame has some level of handwork. Seven prides itself on our handmade frames. The hand issues for monocoque frames are three. Photograph 3 illustrates them: 1) Most of the handwork is hidden inside the frame. 2) Hundreds of carbon pieces with too many ways to have them not correct, with layup schedules that are often obtuse. 3) Many production facilities don't take best-in-class protocols seriously.

"If carbon is so terrible, why does Seven work with it?"

Seven Mitigates the Five Carbon Issues

How can Seven eliminate these issues? It's a combination of:

- Titanium interfaces, joints, and connections

- Titanium drivetrain: Chainstays, bottom bracket, dropouts

- Filament wound tubing custom-made to our specifications

- Liminal epoxy

Seven's Solution to Carbon's Resin Problem

Poor service life and degrading frame stiffness are two problems caused by resin.

Seven's use of titanium interfaces (tubing and machined parts) for the carbon tubes protects the resin. Additionally, we rely on high-strength epoxy rather than resin for strength, stiffness, and durability. Seven's titanium and liminal epoxy combined absorb the vast majority of riding stress.

Resin microcracks due to its 1-2% elongation or flexibility. Seven's liminal epoxy has 10% elongation. This mitigates the carbon and resin delamination process. Seven's titanium has about 20% elongation. The epoxy's 10% is the perfect shear boundary between the brittle carbon-resin and the ductile titanium. This liminal transition layer between titanium and carbon has equal fatigue life to our titanium alloy.

Seven's Solution to Carbon's Stiffness Decay Problem

Bike handling and predictability become worse over time as a carbon frame's stiffness fails.

As shown in Figure 1, carbon's stiffness declines significantly over time. The cause is resin failure. The first stage is microcracking, which reduces material stiffness. In the second stage, the resin begins to delaminate from the carbon. The third stage results in catastrophic frame failure.

Microcracking occurs at joint intersection stress concentrations, not the center sections of the tubing. Remove the low-strength resin intersection, and that removes the stiffness decay.

Seven's 622 chassis all but eliminates this stiffness decay by employing a combination of engineering solutions:

Liminal epoxy: Seven's unique Liminal two-part epoxy provides 10% elongation at the joint interfaces rather than resin's 1%. This means that epoxy is doing the work and protecting the resin. We have never had a carbon tube delaminate with our Liminal epoxy system.

Titanium in high-stress areas: The drivetrain and all tube intersections employ Seven's titanium alloys. These have 20% elongation; the material flex protects both the resin and the epoxy from potential failure.

Carbon-to-titanium interfaces: Our titanium joints have stress relievers built into them. 1) the laser cut points, 2) our logos, and 3) other cutouts. These details allow for more transitional flex, thereby protecting the carbon joints and resin even more.

Seven's custom carbon tube designs: We have our carbon filament wound (details below), so we start with a stronger, more accurate part with no defects or voids. Our custom tubing also has thicker walls than just about any modern monocoque frame — often two to four times thicker. This design provides localized stiffness that mitigates resin damage.

Seven's Solution to Carbon's Overly Stiff Problem

Poor handling and control are hallmarks of a frame that has the wrong kind of stiffness. A harsh ride and feeling isolated from the terrain are also common issues of a frame that's wrongly stiff.

When a carbon frame flexes, even a small amount, the resin microcracks. There's no molded frame solution to this problem. All that bike designers can do is try to delay the inevitable by making the frame as stiff as possible to hold off resin failure. This is a logical solution, except for the resulting poor and sometimes unsafe ride characteristics. In short, the stiffer the frame, the worse the ride. Here, we're talking about generalized stiffness: Stiff vertically, torsionally, and laterally.

Bike suppliers recommend or design with bigger tires, frame or component shocks, and bumpers of all kinds to protect riders from the harsh reality of harsh carbon frames. These are suboptimal solutions; they're heavy, they isolate the rider from the terrain and traction feedback, and they generally worsen the ride control.

Enter Seven's approach to titanium. One of the best attributes of titanium is its ability to bend more than most metals without fatiguing or permanently deforming. By using titanium in the frame's high-stress areas — the joints and drivetrain — Seven can forgo carbon's stiffness requirement. We can make the frame stiff, where it's a benefit, and somewhat smooth or flowing, where that can enhance performance.

Three Planes Solution: In 1997, Seven introduced the concept of isolating three planes in frame engineering. The drivetrain plane, the front-end plane (torsion control), and the vertical plane (Flow). Each of these plays a distinctly different, almost diametric, role in frameset performance and control.

Drivetrain: Stiffness Over All. This is where the classic mentality of stiffness is correct. Seven's approach to titanium gets the stiffest drivetrains of any material, including carbon. By employing this tech in our carbon frames, we've optimized drivetrain performance.

Torsional Control: Some flex and give are critical. We get the right degree of torsion through the use of titanium and our epoxy. Both have sufficient ductility to protect the carbon from over-bending while still achieving the tailored flex ratio needed for optimal wheel plane tracking and tire traction.

Vertical Flow: Tailoring the compliance of the vertical plane provides a better, faster ride. The goal is to keep the tires in contact with the ground rather than allowing them to chatter or skitter over terrain. Proper flow also improves the bike's tracking control. None of this is possible with a full carbon frame.

By employing strategic titanium, stiffness becomes a design tool rather than a requirement.

Seven's Solution to Carbon's Abrasion and Impact Problems

Frame failure and unpredictable service life result from abrasion and poor impact strength.

We address both of these weaknesses through two unique design approaches.

Titanium in high wear areas: The most abraded area on a bike frame is where the tire and chainring meet the chainstays. Mud, chain suck, and chain drop each do fast damage to carbon and virtually no damage to titanium. Seven employs titanium for the entire drivetrain, thereby eliminating that area as a potential failure point.

Damage to the dropout area is eliminated through Seven's use of titanium dropouts and chainstays. Damage from the brake rotor is deflected by the non-drive chainstay. Damage from chain drop at the bottom bracket area is eliminated through the use of a titanium bottom bracket shell. A bike chain is just a kid's version of a chainsaw blade; it makes short work of carbon tubing.

The head tube area is also a high wear zone due to cable rub (both external and internal) and frame bag contact points. On many carbon bikes, this is the area of primary concern. Seven employs a titanium head tube to prevent wear issues.

Carbon tubes that are CNC machined, filament wound, and two to four times thicker. (described in the hand layup solution section below). All of these make Seven's carbon tubes five times more resistant to abrasion than the typical molded carbon frame tubing.

Seven's Solution to Carbon's Hand Layup Issues

Frame failure and unpredictable service life are problems caused by hand layup.

Seven's 622 design addresses this issue in a number of ways:

- A CNC machine does the carbon tube fabrication. No handwork is involved in building the tubing. CNC makes the tubes consistent and defect-free.

- Filament wound carbon tube wall development is part of the CNC process. This provides a much more consistent and predictable tube structure, resin-to-carbon ratio, and overall thickness. Hand-laid-up frames cannot match any of this consistency.

- A precision ground steel mandrel is used to ensure every tube starts with the perfect foundation. This precision also helps maintain perfect epoxy gaps for the strongest, most durable bonding possible.

- Centerless ground precision of the outside diameter after the tube is constructed ensures the most consistent wall thickness and roundness with no voids or defects. Additionally, centerless grinding ensures the diameter is always accurate for perfect epoxy bonding gaps.

- The resin-to-fiber ratio control is optimized because of both the CNC machine and the filament winding process. Controlling resin ratio and consistency is impossible with hand-laid bladder-molded parts. An inconsistent resin ratio results in inconsistent mechanical properties.

"Yeah, but carbon is lighter and more aero. That's worth a lot!

Is it, though? Let's look at weight first.

Weight Has Little Net Positive Affect On Speed

Regardless of all the articles about how lighter bikes are better bikes, at best, saving grams is fairly irrelevant. More likely, shaved grams are causing handling, control, and safety issues that slow riders down.

As a reference point, Seven's PRO frame gravel is about 250 grams heavier than the lightest (claimed weight) carbon frame. That equates to:

- A smartphone and case is about 250 grams.

- A full, large water bottle is about 850 grams.

- 250 grams is less than 2% of a ready-to-ride bike and about 0.3% of the bike plus rider.

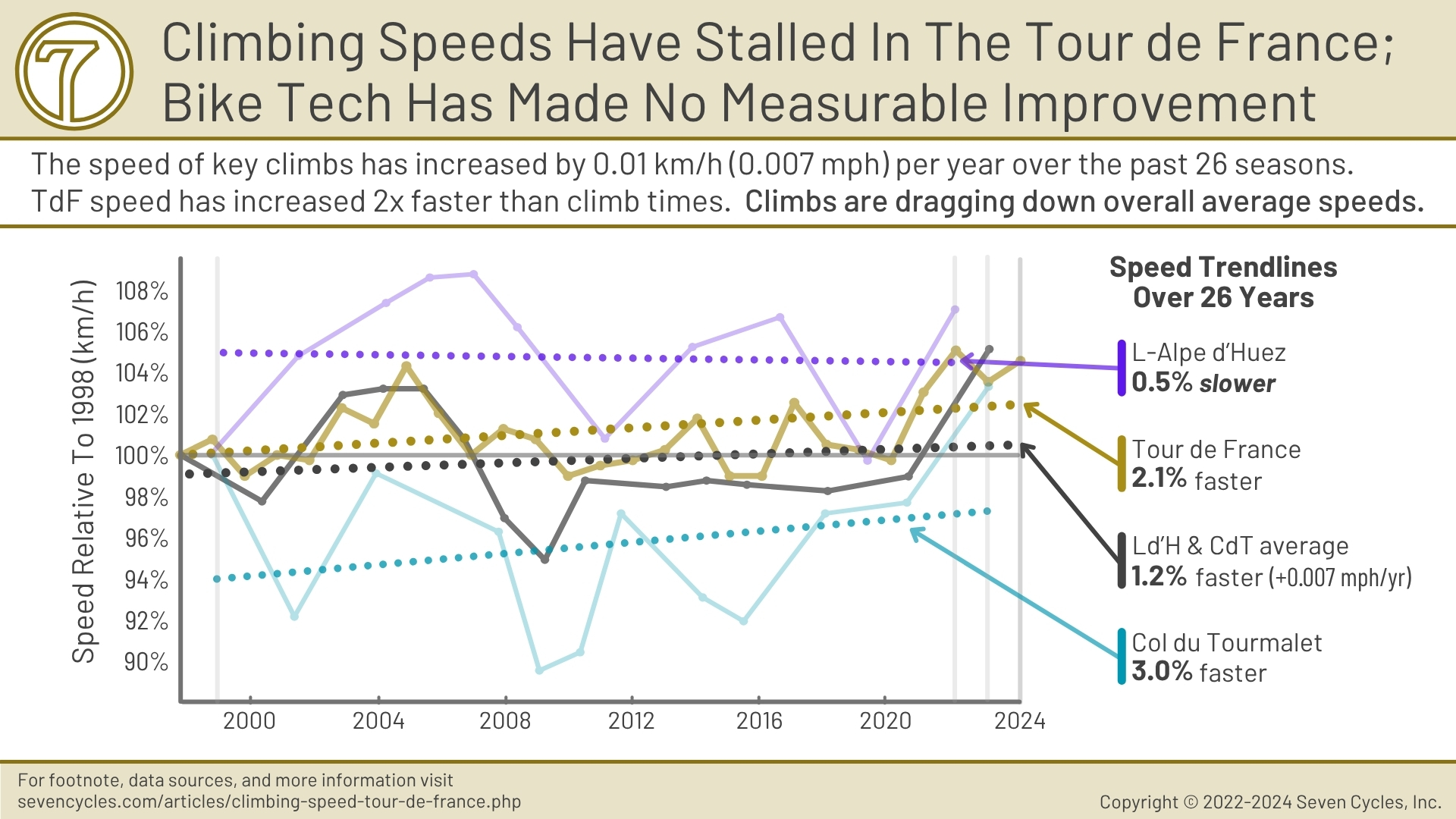

Climbs Are Getting Slower Relative To Overall Race Speeds

Figure 3 illustrates real-world climbing performance in the Tour de France over the past 26 years. Climbing speeds are improving at about half the rate that overall speeds are improving. In other words, climbing is dragging down the overall pace.

Additionally, on the descents, a superlight setup — frame, wheels, bars, stem, saddle, etc. — makes for a hair-raising experience. It's not coincidental that crashes have increased 300% over the past decade while the chase for ever lighter weight continues.

Save 8 Seconds

Another "weight is meaningless" proof that uses real-world data is from ridefar.info's evaluation of the Transcontinental route. It's a bit dense, but the summary is that over a 2,400-mile ride with every kind of terrain and many riders, 200 grams saved is a 0.08% increase in speed. In the normal world, on a 60-mile road ride at 20 mph, this amounts to about 9 seconds.

The math: 5kg = 1.9% faster speed. 200 grams is 4%. 4% of 1.9% = 0.076%. 180 minute ride = 10,800 seconds. 10,800 seconds * 0.076% = 8.2 seconds.

Aerodynamic Gains Are Not Measurable In The Real World

Read Seven's aerodynamic frame design article on the topic. The data is clear. Figure 4 illustrates the fundamental problem: Aero gains don't show up in the UCI World Championship Road Time Trial speeds. If there is any event where aerodynamics is scrutinized for every possible marginal gain, it's the UCI TT WC. No improvements are discernable; therefore, what's the point for non-pros?

Many reasons exist that World Champion speeds should be increasing, regardless of aero evolution. And yet, the improvements are negligible.

Seven's 622s Forgo Modern Carbon Features

That's a good thing!

Seven's carbon bikes have all the features and futureproofing of our full titanium frames.

- No proprietary parts. Check these components before you buy your next bike:

- Seat post: Round. This may sound like a joke, but many modern carbon frames have non-round seat posts sans logic. We offer our frames in the two most common seat post diameters: 27.2 mm (road and gravel) and 30.9 mm (dropper posts and mountain frames). Odd-shaped seat posts are not aerodynamic. (it's all dirty air back there.) Weird shapes that tout suspension elements aren't needed on a Seven because the frame does the smoothening job.

- Headset: Many carbon frames have proprietary headset systems. This may save a few dollars in manufacturing and bearing costs, but the results are short service life and difficulty finding replacement parts. Seven uses the most common 44 mm headset standards; every headset manufacturer offers headsets for Sevens.

- Bottom bracket: Most carbon frames use bearing systems that press directly into the frame. This saves a few manufacturing dollars but results in creaking parts, short bearing life, and likely damage to the frame. Seven offers threaded shells (the industry standard) in T47 and BSA versions. Every bike mechanic can service them. Every bottom bracket and crankset brand has parts for our frames.

- Dropouts: Look online, and you'll find hundreds of replaceable derailleur hanger variants, none of which are interchangeable. Seven offers both UDH and integrated derailleur hangers. This covers all the hanger options. You choose.

- Multiple cable routing options: We offer all the options, including full internal routing, full external routing, and everything in between. Many modern carbon frames are internal only. That's not good.

- Damage management: Seven's 622 design allows for tube REPLACEMENT rather than a carbon-colored band-aid that is the only solution for monocoque carbon frames.

If monocoque carbon is so terrible, why does Seven use a monocoque carbon fork for their framesets?

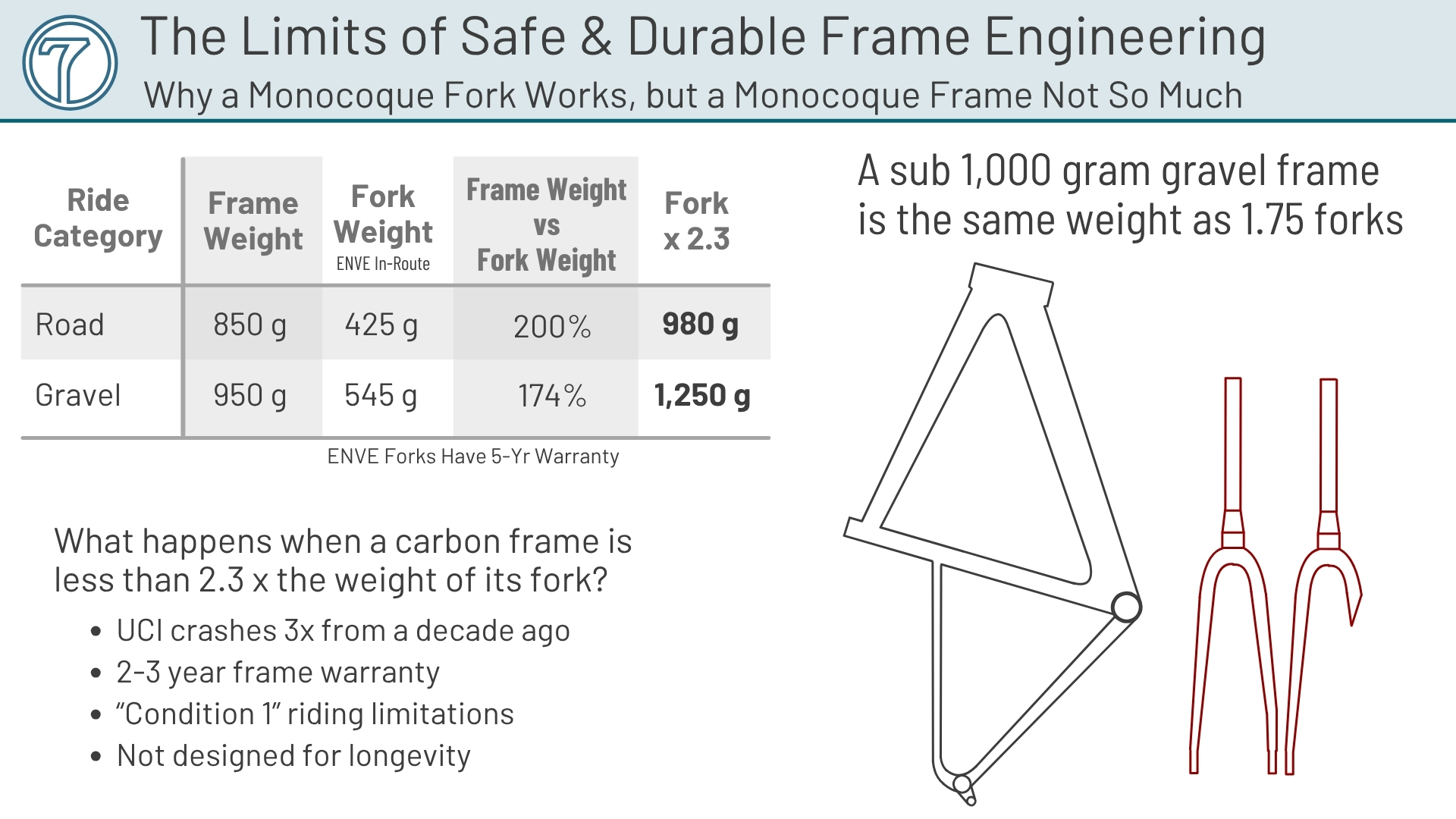

That's a good question and it gets to the heart of the problem with modern monocoque frames. In short, if bike brands sourced frames that were as well built as high-quality forks, riders would be better off. Figure 5 illustrates the issue. The lightest carbon frames weigh less than one and a quarter forks. This is sketchy.

The best forks have 5-year warranties, not lifetime. Frames undergo much more complex and higher stresses due to being chain-driven, with the majority of rider watts going through the bottom bracket. Frames should be at least 2.5 times the weight of a performance fork just to mitigate the worst of carbon's shortcomings.

Forks are proper built. Monocoque frames are under built.

"Condition 1" Language Is Weird

If you've purchased a performance road carbon bike from a large brand in the past few years, the frame is probably designed for “Condition 1” riding constraints, along with several warranty implications.

Numerous large carbon brands use the following language in their owner's manuals. Buried deep in the text that no one reads are a few paragraphs that should give pause. Oddly, the text cannot be found with warranty information.

For context, Condition 1 is considered performance road riding. Condition 1 verbatim text:

"You must understand that:

- these types of bikes are intended to give an aggressive racer or competitive cyclist a performance advantage over a relatively short product life,

- a less aggressive rider will enjoy longer frame life,

- you are choosing light weight (shorter frame life) over more frame weight and a longer frame life,

- you are choosing light weight over more dent resistant or rugged frames that weigh more.

"These frames are likely to be damaged or broken in a crash. They are not designed to take abuse or be a rugged workhorse.

Would you buy a frame that had these usage constraints? Did you buy your high-end carbon bike with the expectation that these were some of the limitations of the bike?

Seven doesn't believe in building Condition 1 bike frames. Sure, a rider can maybe save 200 grams over a rough-and-tumble Seven frame in titanium or carbon. Fortunately, that 200 grams is virtually meaningless in real-world rider performance. Yes, cutting 200 grams will climb marginally faster. However, the bike descends more slowly and, more importantly, does not handle nearly as well, thereby slowing the rider even more, or worse, causing a crash, as the pros do more and more each year.

Don't chase grams. Instead, chase PRs with a bike that removes obstacles to handling, control, and the true source of bike speed.

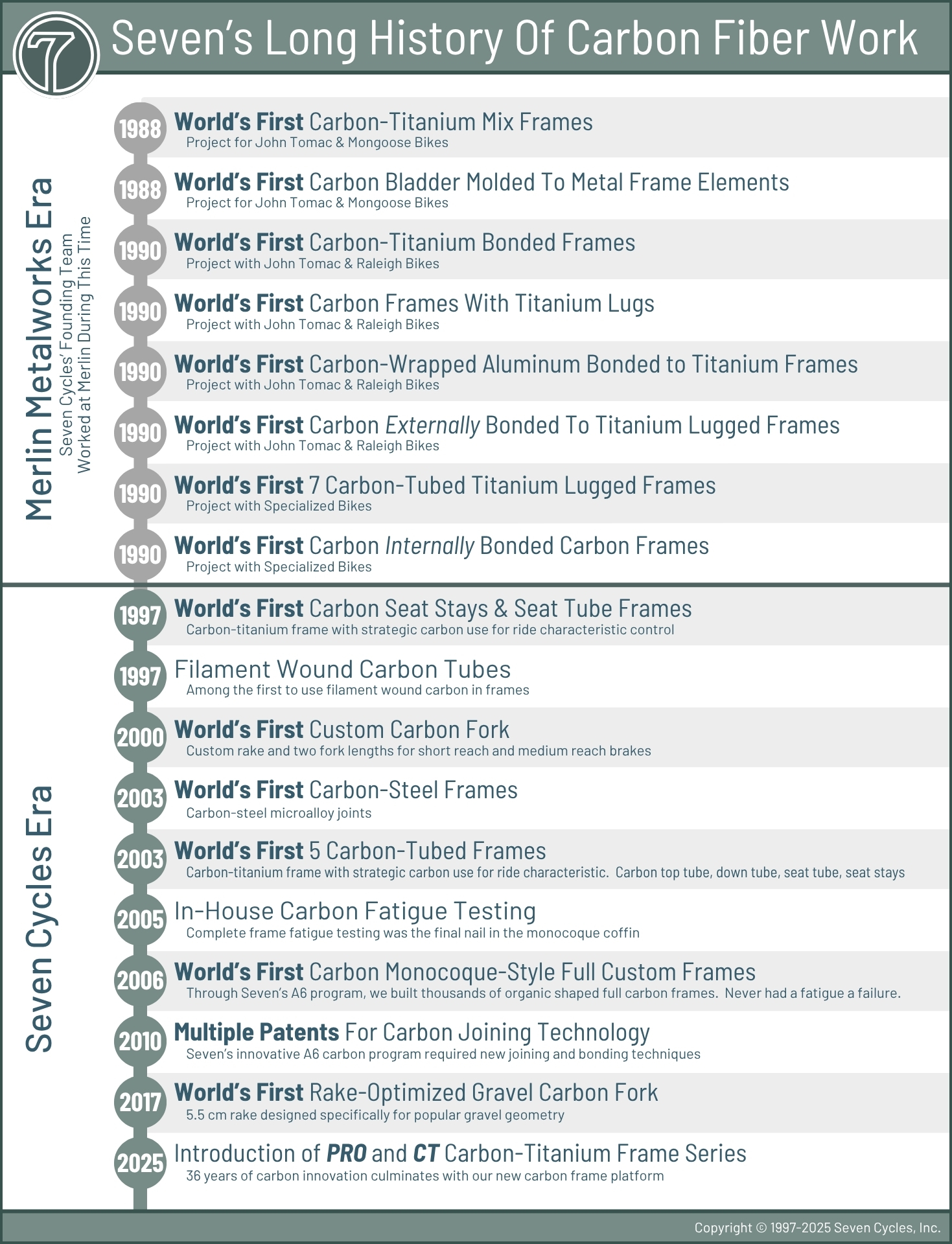

Seven's History with Carbon Framebuilding: 38 years and counting

Seven's history of carbon framebuilding is longer than most and filled with industry firsts and early design innovations that are still used today. We've built more monocoque-style full custom carbon frames than any other builder.