Chain or Belt Tensioning System for Internally Geared Bikes or Single Speed Systems

Chain or belt tensioning

There are three basic ways to tension a chain or belt. We explain the pros and cons or each system below. However, the best method for tensioning a drivetrain is the venerated Eccentric Bottom Bracket, or EBB, system. This is the only system Seven uses even though for many years, we offered all tensioning options. Our decades of custom framebuilding experience have shown the EBB to be superior.

What is an Eccentric Bottom Bracket?

An eccentric bottom bracket is a device used to add tension to a bike chain or belt rather than a traditional derailleur. A standard bottom threads into the EBB insert in an off-center location, which allows tension to be increased or decreased by rotating the EBB clockwise or counterclockwise. When the appropriate tension is achieved, the EBB is held in place by expanding inside the bottom bracket shell.

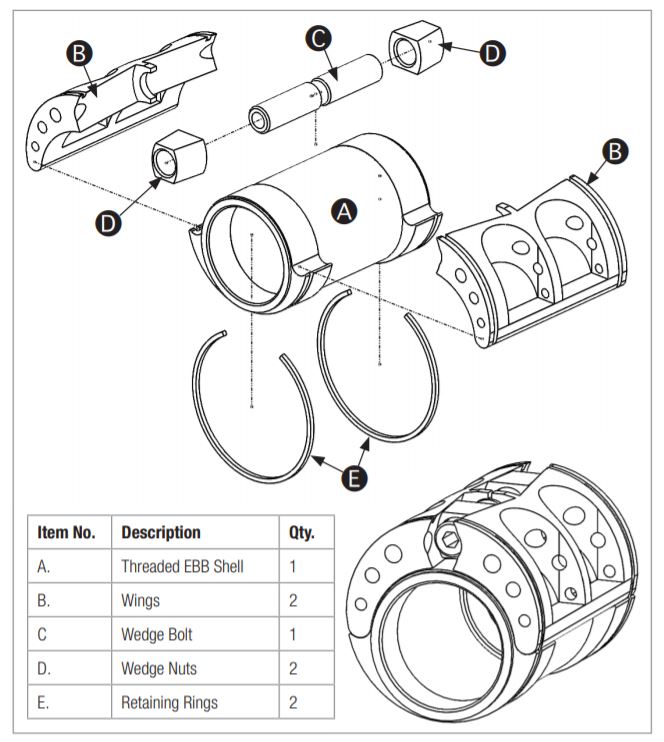

Here are installation instructions and an exploded view of the insert Seven favors.

Chain or Belt Tensioning System Comparison

| Design Aspect or Feature | Eccentric Tension Systems | Horizontal 'Track' Dropout Style Tension Systems | Slider or Rocker Style Dropout Tension Systems |

|---|---|---|---|

| Seven's experience | The BEST system for all the reasons explained here. | We no longer offer these designs after nearly 20 years of data collection and field experience. | |

| Brake system compatibility | Best: Works with any kind of brake system including disc, road calipers, cantilever style brakes, and fixed-gear. | Not easily compatible, and in some cases not at all compatible with road caliper brakes or cantilever brakes. Misaligned wheel installation can create rotor squeal. | |

| Chainstay length & wheelbase length | Best: Provides the shortest possible chainstay and wheelbase. | Requires a longer chainstay to manage the adjustment of the chain or belt. You can't go to the theoretical shortest stay because you need room to adjust. Also, the system requires extra length so you can remove and install the chain or belt. | |

| Wheel system compatibility | Best: Works with any modern wheel system, including thru-axles and quick release systems. | Only works with bolt-on 10 mm axles. Compatible but not recommended with quick release wheels only if chain tensioners are used. Not compatible with contemporary thru-axle wheel systems. Will become more and more difficult to find bolt-on and QR wheels year after year. | Probably works with most wheel systems, but it depends on the generation of rocker style. |

| Changing a flat | As easy as any standard geared bike because the wheel drops down and forward during removal. That movement naturally loosens the chain or belt. There is no need to readjust belt or chain tension after reinstalling. This is particularly helpful for a belt. | If you have rearward track dropout tensioners, you have to adjust/remove them to remove the wheel and readjust after installing the wheel. If you have to adjust them, you'll need to be careful about rear wheel alignment to the plane of the frame. Properly adjusting belt tension is difficult. | Easy. Similar to removing a wheel with a EBB system. |

| Long-term durability | Best: EBBs have been standard on Tandems for decades. Tandems see a lot more load and abuse than a single bike. We've never seen an EBB insert fail in more than 30-years. | Track dropouts are cantilevered away from the frame and this makes them inherently more fragile and failure-prone. Also, popular track dropout designs are too thin and liable to fail. Seven no longer offers track dropout frames of any kind. | A typical rocker-style dropout system consists of 14 parts, including four bolts — that's a lot of parts. Seven's dropouts consist of two parts and are welded in place with no bolts. Also, the entire system is a lot more flexible than Seven's dropout system. Flex leads to failure. Seven no longer offers rocker or slider dropout frames of any kind. |

| Stiffness of the system | Best: Seven's dropouts are 3x stiffer than others, primarily due to our significantly oversized cross-sectional area. | 3x less stiff. Only available with 10mm axles — either bolt-on or quick release — which are significantly less stiff than 15 mm thru-axle wheels. | 3x less stiff titanium portions of the dropout system. Also, the aluminum bolt-on dropout parts are more than 3x more flexible than Seven's welded titanium parts. This is because aluminum's modulus is less than 2/3 of titanium, and the aluminum parts are bolted rather than welded. |

| Ease of tuning and tensioning | Once you've read the instructions, it's simple to tension and tune correctly. | You have to tighten the wheel carefully. This can be frustrating with a bolt-on hub. As you tighten the bolt, the hub wants to move. Depending on the dropout type, it can be tricky to set the proper chain tension while ensuring the wheel is straight in the bike. | You have to adjust each dropout plate somewhat separately. This requires some time and skill. If the dropout alignment is off by 0.010" it will be about 0.040" at the tire. Getting this alignment to be precise takes practice. Also, a misaligned rotor can squeal. |

| Bottom bracket options | Works with any standard English threaded bottom bracket, including 68 mm, 73 mm, and 100 mm widths. | Because horizontal dropouts require 10 mm axled wheels, your options are limited to 68 mm width and maybe some 73 mm width. | Compatible with any bottom bracket system. |

| Versatility for the future | Best: Can work as a geared system or as a single speed. EBB systems have been in the cycling world for decades. There will always be replacement parts available, and the frame shell is open source so anyone can make an EBB Insert system. | Only works as a singlespeed. Yes, you can get a derailleur hanger welded on, but it won't shift ideally with modern 11+ speed drive-trains because the hanger will not be within spec. Quick release wheels are becoming more difficult to find. | You may be able to source replacement plates that have a hanger. These are proprietary designs and not available from multiple sources. |

| Creaking | EBB systems have a reputation for creaking. They do require adequate greasing and maintenance. However, once greased properly, you will get many miles before the need for re-greasing or a quick spray with oil. | When tightened properly, the system shouldn't make any noise. | Popular rocker-style dropout systems consist of 14 parts in two layers. The more interfaces, the more likely to creak or click. |

| Added weight compared to standard frame | Adds about 140 grams including the oversized shell and expander insert. | About 50 grams lighter than a standard dropout system. In part, because it only works with quick release wheel systems. | Adds about 35 grams compared to Seven's standard dropout system. However, rockers are about 100 grams heavier compared to Seven's Awesommetric dropout system that is available with EBB. |

| Cost | $400 includes the expander insert. This is really the only downside to the EBB system, but we think the investment is well worth the many benefits. | Typically the least expensive option. Probably $0 upcharge. Seven no longer offers this option. | Probably not much of an upcharge, if at all. Seven no longer offers this option. |