Endurance riding is not a new segment. From the early days of cycling, riders have sought to challenge themselves by covering distances previously unimagined. But as a category within the broader cycling industry, endurance is now flourishing in a way it never has with the advent of longer, challenge-style events both on-road and off. After spending years working on rando bikes of every stripe, we are now seeing these bikes consolidate around the common experience of riders who are taking on events like Unbound Gravel, the Almanzo 100 and D2R2.

The Seven-sponsored Ride Studio Cafe Endurance Team is made up of three riders who, collectively and in massive solo efforts, will clock more miles on their Sevens this year than most folks will manage in their cars. We are deeply fortunate to be able to work with John Bayley, David Wilcox and Matt Roy. This season they will tackle Dirty Kanza, the Green Mountain Double Century, the Rapha Gentleman’s Race, the Vermont 600, D2R2 and a 1200k brevet of their own design. And events aside, almost every weekend will see these guys spending whole days in the saddle, knocking out century after century, saving up their endurance for big, fast miles on their custom Sevens.

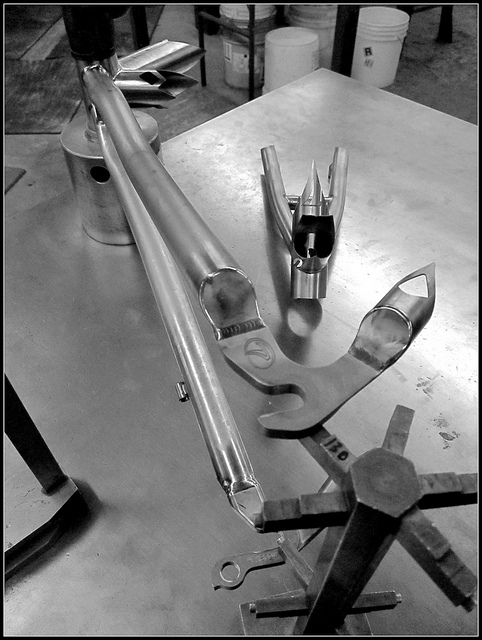

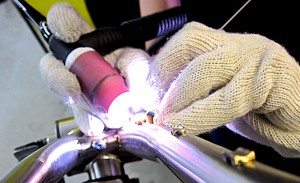

We’ve built each of them a unique, custom, randonneuring bike suited to their personal style and approach to endurance cycling. Comfort and utility get more and more important as the miles pile into your legs and light wanes at the end of the day.

Endurance Team Captain Matt Roy, a Harvard trained immunologist, rides a 622 SLX, the most technically-advanced bike on the endurance circuit. We’ve taken some cues from Mo Bruno Roy’s – last name not coincidental – cyclocross winning Mudhoney PRO. Matt’s 622 is by far the lightest rando bike on gravel, while still boasting the lifetime durability Seven builds into every frame.

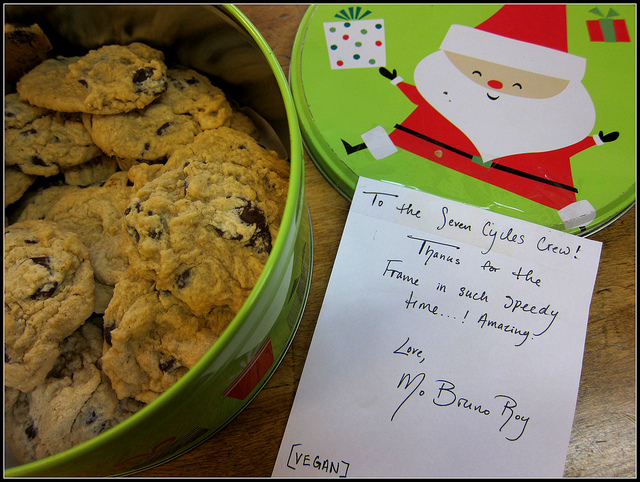

John Bayley values versatility. He is riding an Axiom SL that can run 650b or 700c wheels. His cabling is external for easy servicing and quick adaptation. We finished his bike this week, another speed build that went together in just three days from final design to full assembly thanks to a fair amount of overtime and a group of willing collaborators on the Seven shop floor.

David Wilcox is a quiet, powerful rider, the kind of guy who can ride all day and all night without the whisper of a complaint. His bike is the most simple of the three, an Axiom S with no frills other than hydraulic disc brakes.

As co-sponsors, SRAM has provided the team with their new Force 22 hydraulic groups for each frame. Clement Tires has signed on as well. Working with cutting edge products makes projects like this one even more fun for us.

The Endurance Team sponsorship allows us to explore and experiment in a new and interesting way because these guys will tell us, in the space of one ride, what we might take months of research to learn on our own. Endurance riding pushes bikes to their limits and tests the effectiveness of different component integration strategies. The needs of the long-distance rider also push us to design and integrate practical solutions into each build, the details, big and small, that make all the difference between success and failure.