Seven takes multiple design approaches to drivetrain engineering. Here are a few examples.

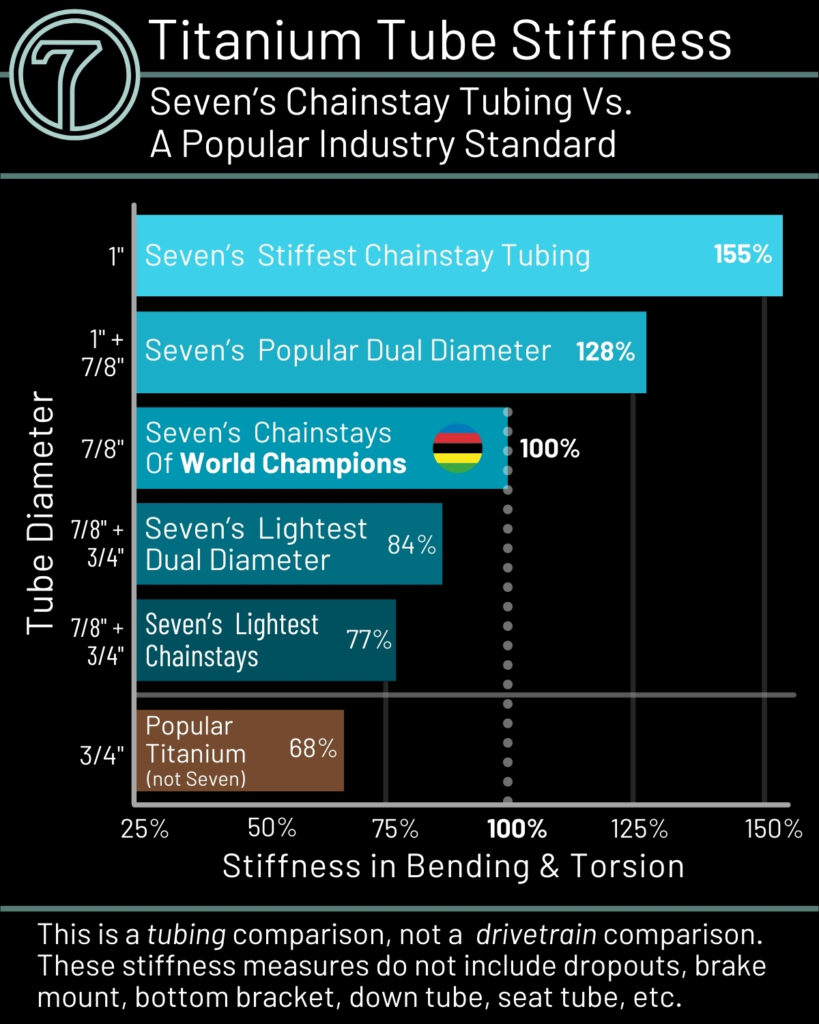

There is chainstay stiffness and drivetrain stiffness. Both are useful to understand and to consider separately.

Chainstays account for about 50% of a drivetrain’s stiffness. The rest of the stiffness comes from a combination of:

- Dropouts & axle interface: Seven’s are machined titanium and the stiffest by about 3x compared to any others we’ve tested — titanium or carbon.

- Disc brake mount: Seven’s is bolted to the dropout rather than being welded to a thin tube or a molded carbon shape.

- Bottom bracket shell: Seven’s is machined from the thickest material available.

- Down tube & seat tube: We use a number of tube sizes and walls to tailor drivetrain stiffness.

See Figure 1 for more details.

Next, we turn these parts into a frame. Riders choose either of our framebuilding methods:

- Seven Simple-CustomTM program, where we offer three tubesets that are both size-specific and usage-specific.

- Seven’s full custom program, where we individually design the tubeset from the ground up.

Simple-Custom

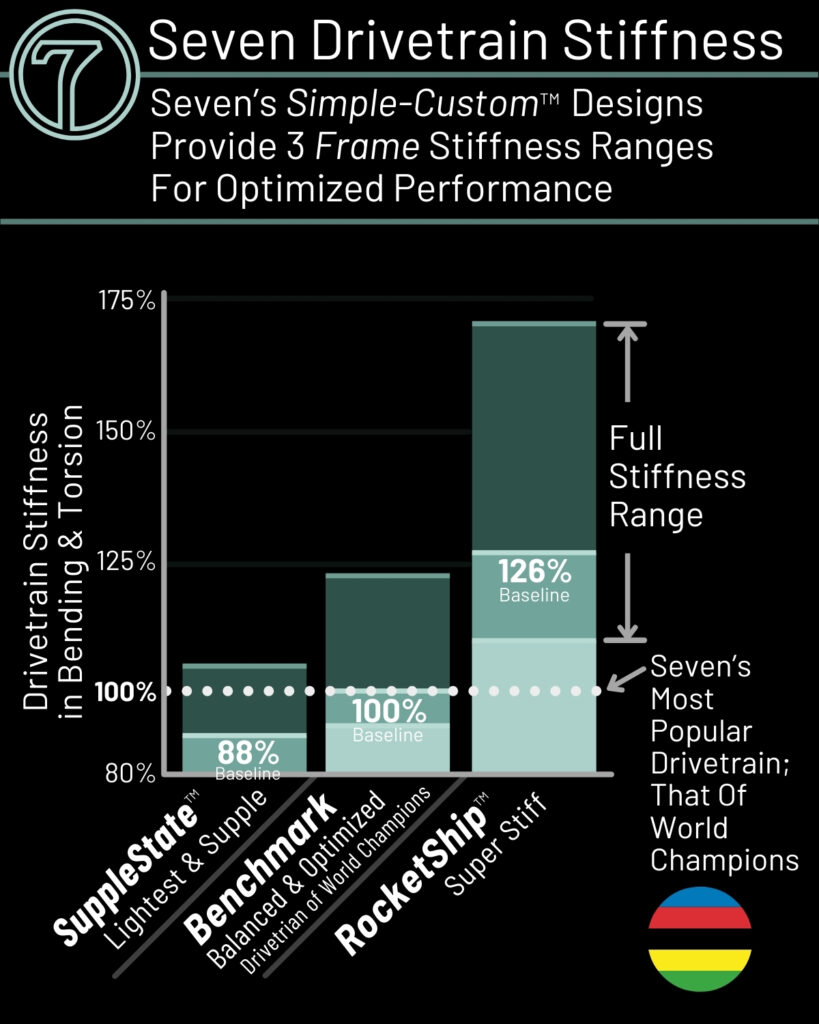

We offer three levels of frame stiffness. See figure 1 for an example of the differences and overall range of stiffness.

- RocketShipTM tubeset is super stiff. Typically about 25% stiffer than our Benchmark drivetrain. As much as 70% stiffer for our largest frames. This is a specialty tubeset that is not ideal for every rider.

- Benchmark tubeset is the sweet spot; it’s balanced and optimized for most riders. For example, all of our world champions have ridden our Benchmark tubesets.

- SuppleStateTM tubeset is super smooth and plush. This is a specialty tubeset for specific types of riding.

Specificity

Each tubeset is size-specific and function-specific.

Size-specific: We typically offer 12 frame sizes for each Simple-Custom design. Each of these 12 has a distinct and different tubeset from the other 11 sizes.

Use-specific: We have over 30 Simple-Custom frame designs (gravel, allroads, mountain, bikepacking, etc.). Each of these models has a distinct tubeset we optimize for the use. For example, an allroads benefits from a different tubeset than a gravel bike.

20-Plus Titanium Tube Sizes

We start each design with a choice of more than 20 raw tubes or starter stock. From there, we butt, machine, manipulate, modify, and bend each tube to optimize it for its mission. See Figure 2 for an image of 23 distinct tube profiles.

Full Custom

Concerning drivetrains, in our full custom program, we can make drivetrains over 250% stiffer than our popular Benchmark. While that kind of stiffness is not beneficial to most riders, it provides a good illustration of how extreme our full custom program can get.

Figure 3 shows how stiff the chainstay material can get, 155% stiffer than our Benchmark. Once we add in all the drivetrain elements (dropouts, bottom bracket, etc.), we can nearly double that stiffness.