Master Frame Welder

You have welded titanium or stainless steel frames at a bike company for at least two years. This should total about 100-300 frames. At this point, your weld quality should be near perfect. Your error rate should be near zero.

If you have the tenacity, welding chops, and commitment to training constantly to weld at the level of our mentor team, we'd love to talk with you. Apply now.

Visit our career page to view a list of other available roles.

If this is welding skill set requirement is above your current ability, check out our other welding roles that may be more appropriate:

- Frame Welding Journeyist: You have at least two years of TIG welding thin wall stainless steel or titanium tubing and sheet.

- Frame Welding Apprentice: You have at least two years of TIG welding work experience.

Welding Role Summary

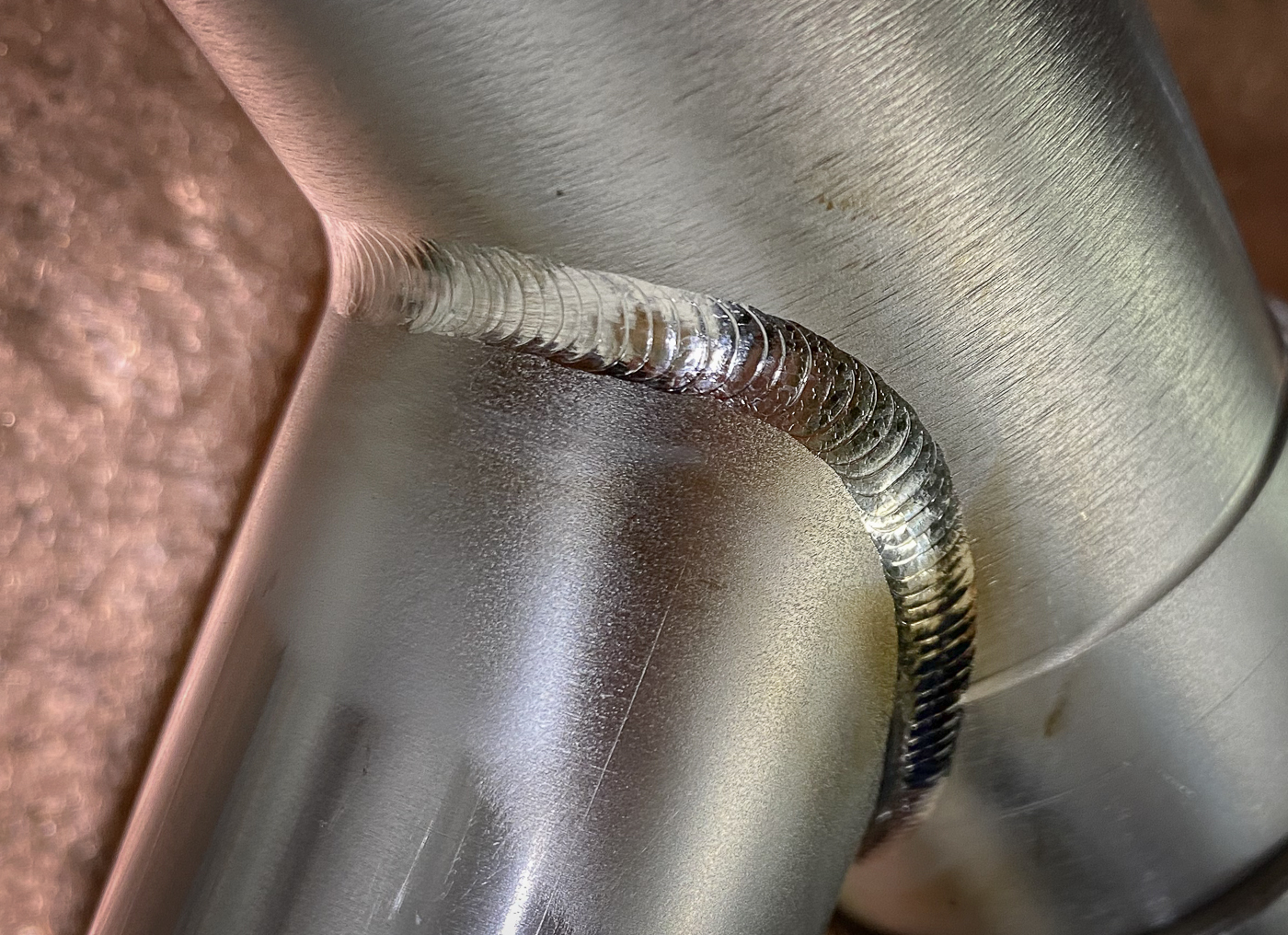

Seven's TIG welding job entails taking individual machined tubes and parts and welding them into the most beautiful, most durable, and straightest frames ever made. This requires extreme skill, practice, confidence, and focus.

Every frameset we weld is custom-designed for a specific rider. We don't build batches. You focus on one frame at a time to ensure it's straight and true. Our weld fixturing is extremely adaptive, so we can build and weld any size and type of frame.

As a welder, you also machine some elements that get welded onto the frame. You use a number of fixtures, hand files, drills, and dial calipers as well. We often use deceptively simple tools to make perfect frames.

You will weld customized bicycle frames every day. It's the closest thing to perfection that the customer will ever ride. The next day you do the same thing again and make another customer happy. This reinforcing loop goes on and on but never becomes boring because every frame is different.

During their tenure, welders at Seven almost always become among the best frame welders in the world. Within three years, you will have welded more custom frames than most builders craft in a lifetime. Your welding value will be second to none.

As a Seven welder, you work with the most experienced team in the industry, including Tim Delaney, who 38 years ago, ushered in the titanium welding standards that most builders use today. You'll learn from a welder-mentor team with more than 90 years of combined frame welding experience. Your learning opportunity is unlike any other in the industry.

If you're excited by the idea of becoming one of the best welders in the bike industry on a fast track because you're working with the most experienced build team in the industry, apply for the welding job.

Required Experience

- Two years of welding titanium or stainless steel frames at a bike company. This should equate to at least 100 frames.

- You can weld both pulsed and non-pulsed TIG with nearly identical results in appearance and fatigue strength.

- You have a portfolio or set of photos that shows your welding quality in titanium or stainless steel.

Ideal Qualifications

- You have multiple welding certifications.

- You can service and maintain TIG welding machines, torches, and purge lines.

- You love cycling and have a particular interest in high-end performance bikes.

- Bike industry experience of any kind.

Welding Responsibilities

- Welding frames and parts.

- Participating in Seven's team goals for safety, accuracy, quantity, and continuous improvement.

- Commitment to developing capabilities and skills to become a better welder and teammate.

- Equipment and machine maintenance.

- Professionalism: You understand what it means that your team counts on you. You are dependable. You do what you say you'll do. You communicate clearly.

- Our welders work independently in most situations but also as part of the welding team and as part of our entire frame builder group.

Compensation: Competitive hourly wage and benefits relative to other small businesses. Benefits include health insurance coverage (Seven pays a portion), flex time, paid time off, bike industry benefits, a retirement plan, and more.

Work location: On-site at Seven Cycles in Watertown, MA.

Apply for this Job

If this role sounds like what you've been dreaming about, apply for the job here. Do not call us. Do not contact us at other Seven email addresses. If you have questions or want more information, email us using this form, and include your resume and cover letter.

About Seven Cycles, Inc.

We started Seven Cycles 29 years ago. Not only has our founding team been building bikes longer than just about any other multiperson handmade framebuilding company in the United States, but we are also the largest custom bicycle builder in the world. We've won numerous awards and have countless industry firsts to our credit.

Seven's mission is to build bikes that exceed riders' aspirations.

Seven Cycles is an equal opportunity employer. We offer competitive salaries and benefits in comparison to other small businesses. We support work-life balance and healthy mental and physical working conditions. Seven fosters a fast-paced, values-driven environment, placing particular focus on our employees, customer satisfaction, product quality, and innovation.

Contact us to join our team.