https://www.facebook.com/56020902839/videos/482157645686033/

Category: Articles

The Connaught 600

First the photo, this one worth 2,000 words, we think.

Even without any context, we found ourselves wondering, if you could ride a bike there (where?) why would you ever ride anywhere else? If you’re looking for the spot, it’sat the Ceide Fields a Neolithic field system in Mayo, Ireland.

We met Noel, the rider, through our friends at Cyclefit in London. Noel is an accomplished audax rider from Ireland, and we painted his Axiom SL to match his favorite place to ride, as well as to honor Audax Ireland. The photo was taken during the Connaught 600, a 600k event by the organiser of the Wild Atlantic Way Randonee.

Winning at NAHBS 2019

There were so many beautifully made bikes at NAHBS from builders of all sizes, that we were honored and humbled to walk away with the awards for Best Road Bike and Best Gravel Bike as well as being named a finalist for Best Mountain Bike.

Why did our bikes win?

For the judges, it seemed, everything came down to technology. Among the carefully made bikes at the show, the lion’s share of the titanium models were straight gauge bikes with off-the-shelf dropouts. Most had stunning paint jobs. They all looked great, but as bikes, they weren’t necessarily difficult to execute and didn’t always express an ability to customize deeply.

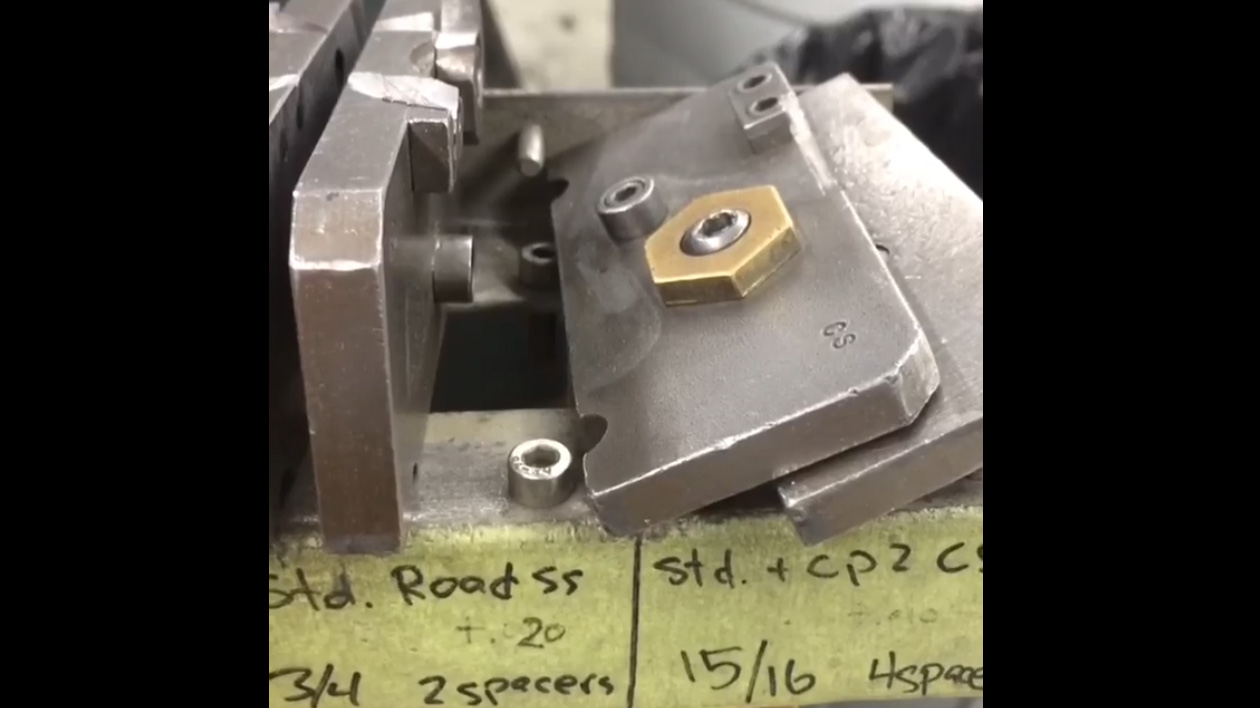

Our winning road bike, the Ultimate Axiom Disc, improved on the simpler builds at the show in three key ways. First, the level of tube butting was beyond many other builder’s capabilities. We butt our own tubing, in-house, based on rider profile and customize down to one-thousandth of an inch.

For the show bike, we also butted the custom Ti seatpost, chainstays and seatstays. Our XX upgrade package also modifies the standard tubeset in about a dozen ways that other builders aren’t yet able to replicate. The mix of one-inch chainstays and Moto seat stays comprise the sort of purpose-built modifications that go beyond looks, deep into technological improvements that make the bike faster, make it handle better, and improve its traction.

Finally, the bike is finished beautifully using a method, MCT (or Multimedia Color Technique), developed in-house at Seven. MCT is a layered finish system that uses bead-blasting, dry stenciling, other materials and methods, clear coat and matte finish, as well as regular wet paint and other surface effects, depending on the design.

For the gravel category we built a one-of-a-kind Evergreen PRO SL, another bike that showcased our ability to design and execute a bike deeply refined for its purpose. For this bike, a fast-riding, packed-dirt rider, we incorporated a one-inch Chopped chainstay into a classic Seven Ti/carbon frame. The blend of materials, which produces stiffness in all the right places and compliance everywhere else, is perfect for going fast off-road.

The Chopped chainstay, which had show-goers gasping for three straight days, shortens the rear of the bike, which boosts traction, acceleration, and agility. We finished that bike with another eclectic MCT design with matching wheels, headset and hubs.

Our takeaway from NAHBS is that technology matters. Show bikes need to look great, but there has to be more beneath the surface. The judges responded to our work in exactly the way we hoped they would, but riders also recognized what was going on with each bike and appreciated it.

The good news for you, our riders, is that Seven doesn’t really build show bikes. Every bike we had at NAHBS can be ordered by any rider at any time and delivered on our standard timelines.

Contact to find out more.

Mike Bybee’s Sights of the Southwest

It’s becoming something like a tradition, our friend Mike emails us about his new calendar, sends us a few, and then we spend the year daydreaming about riding the Southwest US where he rides, camera-in-tow, and gets up to some serious bikepacking.

Mike is a Seven rider, and he is always kind enough to include us (we’re June this year!). If you’re looking for something inspiring, pop over to his site, gaze at the vistas, and then go ride your bike.

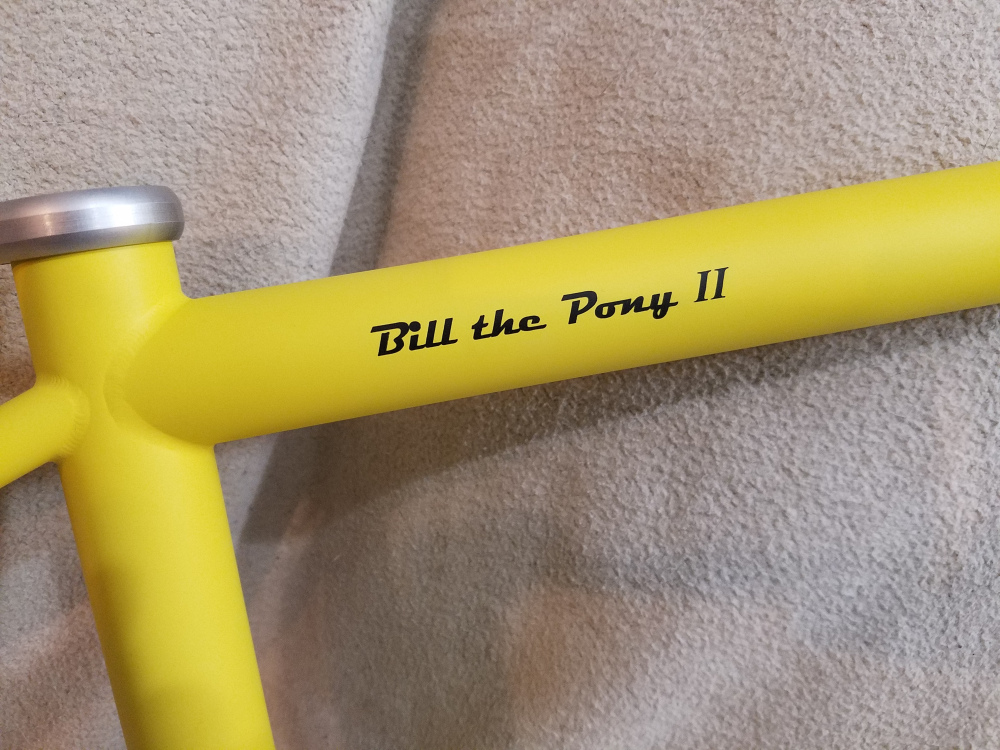

Dan’s Expat S, or Bill the Pony, II

We spend all our time building custom bikes and talking about custom bikes and trying to tell the story of custom bike building. So it’s sort of mind blowing when you work with a customer who fully documents the process from their own perspective, and you get to read it and it opens your eyes to what it is you really do.

A recent Expat S build, for Dan H, gave us this opportunity. Dan has an excellent, personal cycling 7, and he starts right from the beginning on this project, narrowing down his choices and ideas. Then he orders his Seven and does a deep dive on the details. Then we detour into naming the bike, a process that is equal parts goofy charm and intimate portrait of how bicycle riders bask in the culture of riding bikes. That part was pretty inspiring. At last, Dan comes to visit while we are building his bike, and then we deliver it to him.

You can read for yourself that Dan is quite a character, a passionate cyclist, a big thinker. Getting to know our riders is one of the very best parts of doing things the way we do. That Dan is local to Seven and comes to us through the excellent Ride Studio Cafe is great, but we have had this sort of experience with riders from Indonesia, the Philippines, Australia, Germany, Spain, the UK, Texas, California, and Ohio, too.